Returning Customer

I am a returning customer

Register Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Congratulations! Your new account has been successfully created!

You can now take advantage of member privileges to enhance your online shopping experience with us.

If you have ANY questions about the operation of this online shop, please e-mail the store owner.

A confirmation has been sent to the provided e-mail address. If you have not received it within the hour, please contact us.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

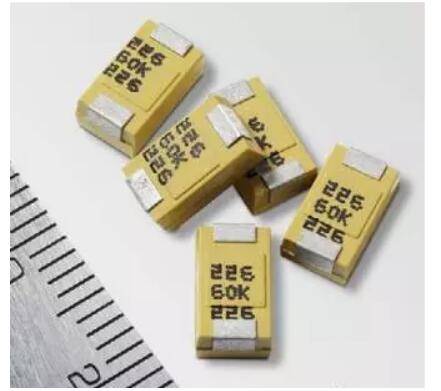

Small parts, high-end personal care products, electronic components, wire and cable manufacturers often require traceability of their products. To optimize supply chain traceability and meet customer needs, high-quality printing of small parts and materials with limited area requirements must be done.

Challenges:

Producers are facing the need to print more in the same (often limited) space. The challenge comes from the need to accommodate more customer information, as well as internal and external traceability coding. Material space is often limited in such applications, which is a challenge for clear-legible, easy-to-print coding of traditional small-character (CIJ) printers. In addition, keeping unofficial production downtime or printing errors without maintenance is paramount to achieving today's efficiency goals.

The advantage of Raymond CIJ printer

Raymond CIJ Printers are specifically designed for the actual application needs specified by the manufacturer that require micro-character printing. Therefore, all design features are designed to improve the legibility of the print at high speeds (compared to traditional CIJ printers), as well as provide advanced features that increase productivity and increase uptime. Raymond HR Micro Character Printer is capable of printing multi-line texts, 2D barcode and linear bar codes, as well as standard 90 DPI resolution for printing more relevant information in a smaller space. In addition, the HR ink range includes halogen-free formulations that meet stringent industry standards that are ROHS compliant and suitable for many applications.

Raymond High-resolution micro-characters printer,What are the advantages?

Smaller nozzle size

In order to print clear and legible micro texts, you need to reduce the amount of ink per droplet to less than a traditional CIJ system. To print the desired content in a smaller space, the drops are closer together; if they are not small enough, the drops interfere with each other, causing the created graphics to be blurred. The HR Micro Character Printer uses a high-precision nozzle with a diameter of 40 μm (less than half the diameter of a human hair) designed to print high-quality, clear, legible text with print characters down to 0.6 mm height.

Higher nozzle frequency

Drop rates faster than 100,000 drops per second deliver the print quality you need without sacrificing speed. Compared with other inkjet printers with lower nozzle frequency, more drops of this frequency drop can improve the coding quality and speed of printing.

Uptime advantage

Your production plan is very important, with little or no disruption to maintenance and unplanned downtime, which is critical to productivity.Raymond Printer Clean flow technology reduces ink build-up on the nozzle end, which extends nozzle cleaning intervals up to 300 hours. When the ambient temperature and humidity vary throughout the day and in different seasons.

Dynamic calibration technology helps ensure print quality consistency by automatically adjusting printer settings. Finally, Inkjet ink cartridges last up to 14,000 hours, helping to minimize necessary maintenance intervals.

Applicable industry

Although there are multiple applications that need to print multi-line micro-literal texts, there are additional requirements in the electronics and component industries, including:

1)Provide consistent print quality over longer production intervals

2)Clean indoor environment, to eliminate dirty ink and solvent supply

3)The ink meets the specific requirements of resistance to physical and chemical resistance, while meeting industry standards.

Cartridge system without waste, no mess

The smart cartridge ink and solvent system uses a needle film design to virtually eliminate ink and solvent leaks during replenishment. Due to the smart design of the inkjet ink cartridges, the right proportioning of ink in the mixing tank keeps the production running for hours, so ink and solvent boxes can be replenished during shifts. Finally, the smart chip on each cartridge prevents downtime due to incorrect ink and solvent cartridge insertion, and full ink and solvent levels are clearly visible on the printer interface.