Returning Customer

I am a returning customer

Register Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Congratulations! Your new account has been successfully created!

You can now take advantage of member privileges to enhance your online shopping experience with us.

If you have ANY questions about the operation of this online shop, please e-mail the store owner.

A confirmation has been sent to the provided e-mail address. If you have not received it within the hour, please contact us.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

Laser marking technology has penetrated into all walks of life,the use of laser marking machine is no consumables,pollution-free environment,high processing efficiency,at the same time to prevent fake and shoddy.

The most common items in our daily life,such as printing the production date, are the food packaging.From the printed packaging information,we can know the information about the product's service life,the place of production,the ingredients contained in the food,the storage conditions and so on.In the past, most of these messages were printed on ink-jet printers,which could easily be erased and changed without a good anti-counterfeit effect.Now most of them are marked with a laser marking machine.Laser marking uses laser marking to locally irradiate a workpiece with a laser of high energy density to vaporize or change the color of the surface material,thereby leaving a permanent Marking of a marking method,once spray can not be changed and erased,to better ensure the quality of goods and allow some unscrupulous traders inorganic.

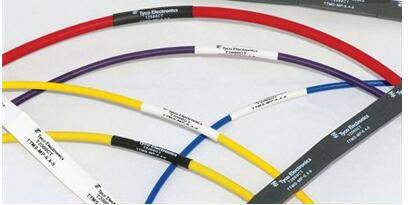

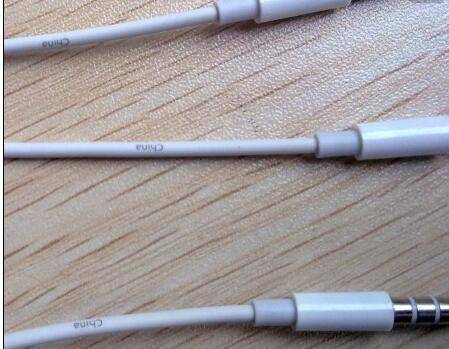

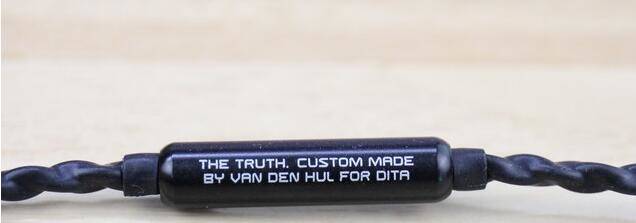

The rapid development of laser technology today,the application of laser technology has been deep into the many fields of current industry, excellent performance advantages,is now bringing new vitality to industrial technology.Wire and cable marking laser marking machine has also become a technology and means that once the wire and cable products marked with the corresponding date,lot number, brand, serial number, two-dimensional code and other information,you can not change,This is of great significance to the security of wire and cable products nowadays.Can effectively resist some unscrupulous traders fake,shoddy and goods,effectively regulate the current wire and cable market,the quality of wire and cable plays an important role. And laser marking the entire process using computer software to control,not only processing flexibility,but also accurate,can effectively reduce the wire and cable product processing rate of non-performing.Can be said that the rapid development of laser technology today,laser marking technology in wire and cable applications has become an irresistible trend,especially with the current fiber laser marking machine and other related advanced laser marking equipment,making the laser mark in Now the advantages of wire and cable applications more obvious

The disadvantage of the ink jet printer.

The use of ink inkjet printer http://www.raymondcoding.com, pollution and the use of high cost, huge ink consumption. It is understood that a medium-sized enterprises purchase ink costs one year to reach 40-50 million or even millions.The cost of laser coding equipment pre-investment will be higher,but it does not have any supplies,power consumption is relatively low,a lot of long-term absolute advantage.So the laser printer has been from the food, beverage and other industries slowly began to wire and cable,battery,electronics,plastics,packaging, etc.