Returning Customer

I am a returning customer

Register Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Congratulations! Your new account has been successfully created!

You can now take advantage of member privileges to enhance your online shopping experience with us.

If you have ANY questions about the operation of this online shop, please e-mail the store owner.

A confirmation has been sent to the provided e-mail address. If you have not received it within the hour, please contact us.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

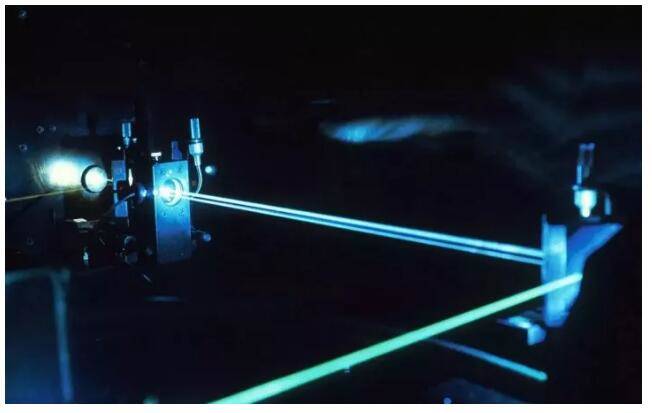

Laser marking technology uses a laser beam to mark permanent surfaces on a variety of different materials. Marking effect is through the evaporation of surface material to reveal the deep material, or through the light can cause chemical and physical changes in the surface material and "mark" or burn through the light part of the material, showing the desired etching Pattern, text. At present, there are two main "hot processing" and "cold processing" marking methods:

"Hot working" a laser beam with a higher energy density, which is a concentrated energy flow, irradiates the surface of the material to be processed, absorbs the laser energy at the surface of the material, and generates a thermal excitation in the irradiated area so that the surface of the material Coating) temperature rise, resulting in abnormal, melting, ablation, evaporation and so on.

"Cold working" photons of (UV) light with a high energy load that interrupts chemical bonds in materials (especially organic materials) or in the surrounding media to non-thermal process failure of the material. This type of cold working is of particular significance in laser marking because it is not thermal ablated but does not produce the "thermal damage" side effects that interrupt the cold stripping of the chemical bonds so that the inner and the vicinity of the surface being machined are not Produce heat or heat deformation and so on.

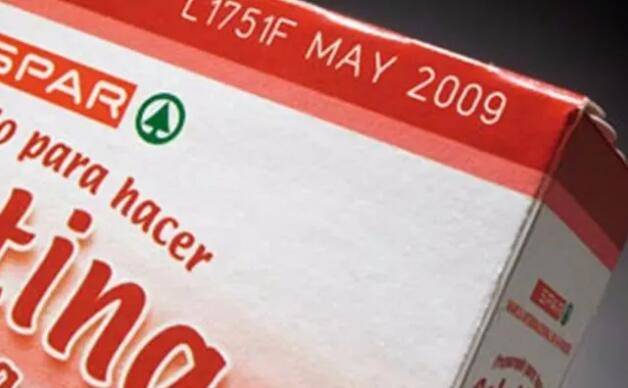

The essence of a laser is a device that converts electrical energy into light, with a life expectancy of hundreds of thousands of hours, without consuming any excipients or consumables. Relative to the inkjet printer, almost no supplies maintenance-free equipment. After the focus of the spot is usually 0.03mm ~ 0.1mm, it can mark the very fine characters or patterns. Such as optical marking machine marking the smallest character to 0.2mm. Laser marking is essentially a destructive "removal" process, whether it is a "hot" or "cold" process, which can not be resumed once the material has been "removed", unlike the "incremental" Processing, can be artificially wiped off. In addition, the ink contains toxic elements such as lead and other heavy metals in the food and drug industries is the use of taboo, and laser processing does not bring any substance, does not produce harmful elements, are non-toxic and almost zero emissions processing equipment.

Here is the smaple we marking on different materal:

If you are interested in,please take a check for our website:

http://www.raymondcoding.com/laser-marking-machine/UV-laser-marking-machine