Returning Customer

I am a returning customer

Register Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Congratulations! Your new account has been successfully created!

You can now take advantage of member privileges to enhance your online shopping experience with us.

If you have ANY questions about the operation of this online shop, please e-mail the store owner.

A confirmation has been sent to the provided e-mail address. If you have not received it within the hour, please contact us.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

Beauty is the nature of every woman, and jewelry is an indispensable accessory for women. When choosing jewelry, texture, color, appearance, workmanship and uniqueness are all factors to consider when purchasing. Since most of the jewelry uses expensive raw materials such as gold, silver, platinum, and diamonds, the requirements for the production process are also very high. As a advanced processing equipment, laser marking machine has become the first choice of many jewelry processing manufacturers because of its unique advantages.

With the development of the jewelry industry, traditional processing methods have been unable to meet the needs of the market. As an advanced processing equipment, the laser marking machine has fast processing speed and high efficiency. It can be used for non-contact marking processing. There is no material loss for jewelry products, and the marking pattern is fine and beautiful, durable and laser marking. The marking method of the machine is also very flexible. Simply input the specified text or pattern in the software, and the laser marking machine can mark the desired effect in a few seconds. As a result, the customer's individual needs are also met.

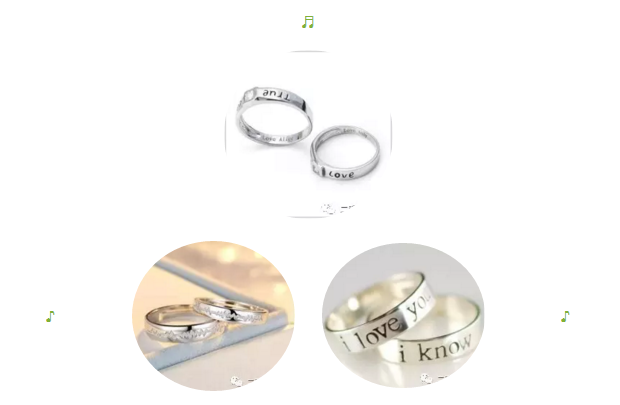

Laser marking machine marks text on the ring

The high-precision characteristics of the laser marking machine are ideal for permanent wear-resistant markings on precious and delicate jewellery surfaces such as rings and necklaces. In today's jewelry market, personalized markings are favored by customers, such as special words, greetings and personalized patterns on jewelry. In addition, the laser marking machine can also realize various markings on the surface of most materials such as copper, stainless steel, silver and gold.

Laser marking machine to create a unique wedding ring

Fiber laser marking machine highlights advantages

1. The marking speed is fast, the efficiency is high, the batch processing time of the workpiece is short, and the profit per unit time and individual products is maximized;

2, fiber laser has a long service life, stable laser output power, high reliability, 100,000 hours maintenance-free;

3, high electro-optical conversion rate, no power coupling loss, no consumables, saving operating costs for customers.

Highlights of laser engraving machine

1. The beam quality is good, the precision carving of the tiny workpiece can be carried out, the slit is smooth and beautiful, the engraving speed is fast, and the customer has an efficient and economical processing experience;

2. The machine has high stability and long service life, and can meet the industrial production demand for long-term continuous processing;

3, high electro-optical conversion rate, low energy consumption, saving a lot of use costs for enterprises;

4, laser engraving and punching special software, powerful, easy to operate, do not have to worry about the operator's frequent changes;

5, special machine customization ability, can be tailored to customer needs.