Returning Customer

I am a returning customer

Register Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Congratulations! Your new account has been successfully created!

You can now take advantage of member privileges to enhance your online shopping experience with us.

If you have ANY questions about the operation of this online shop, please e-mail the store owner.

A confirmation has been sent to the provided e-mail address. If you have not received it within the hour, please contact us.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

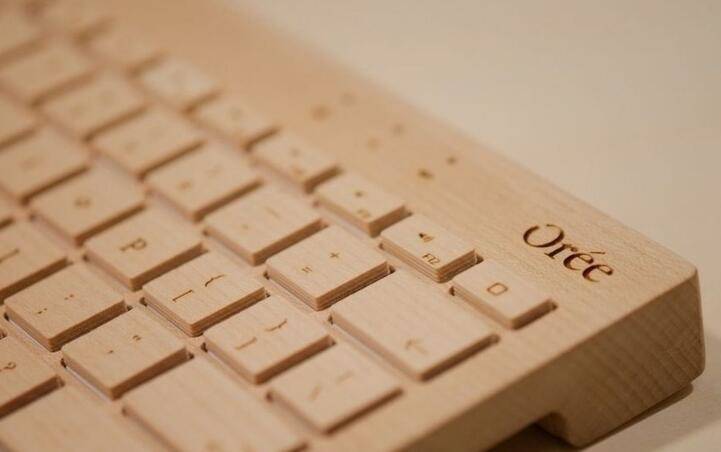

Wood products are made of wood,after processing, the products formed,mainly can be divided into the following categories:furniture wood products,office wood products,wood products,horticultural wood products,wood products of life,and now high-tech Wood products and so on.In everyday life we saw wood products are unique,different from the kind of simple without modification.

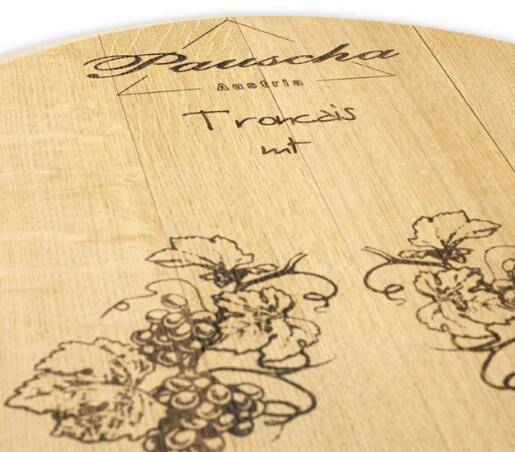

With the rapid economic development and continuous improvement of people's living standards,daily necessities have also been gradually raised in terms of quality and appearance.Furniture as the most important part of wood products,as the life is no longer a simple article,but the daily necessities of art,to their own life to bring a different taste and warmth.As we all know, in the past to make wood products have chic exquisite designs and other effects,often require skilled craftsmen fine carving, grasp the intensity of each carving,in order to make the overall effect without losing the charm.However, with the continuous improvement of labor cost,the carpentry products that get such exquisite designs are not only very expensive,but also can not be effectively guaranteed in the quality of the products.

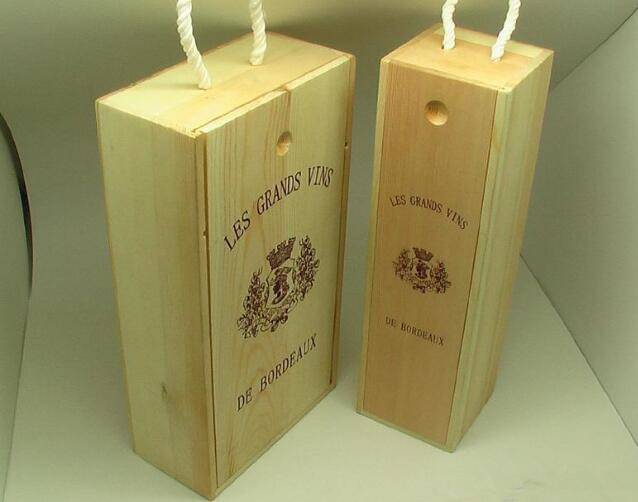

Then the question came,how can we effectively solve the cost caused by rising labor costs,while the quality of the product can be protected?The use of laser technology can be very good to solve,because the laser processing and traditional processing is different,the current laser processing is the use of high energy density laser beam into heat,instantaneous thermal decomposition and carbonization of wood to remove some of the material,wood Surface processing products exquisite patterns, patterns and text. At the same time the entire process,the use of computer control,do not like the traditional processing as superb technology,even very complex patterns, the use of computers can be very easy to process. And the laser can form a very small laser beam after focusing,so even a very small wood marking,laser processing can be both, not as traditional processing,not only in the processing accuracy can not reach above,while the processing effect It is difficult to guarantee.As the traditional wood products mostly pure hand-carved,time-consuming,laborious,requiring processors must have superb craftsmanship and artistic sense of high threshold, so the development of wood products industry is particularly slow,but now with the laser marking machine ,Laser cutting machines and other laser equipment,which greatly reduces the wood processing industry costs and processing threshold,while improving the effect of processing wood products,wood products in the market more competitive advantage.

In short,the advantages of integrated laser processing and fierce market competition in the marking of wood products should be the preferred laser marking machine.