Returning Customer

I am a returning customer

Register Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Congratulations! Your new account has been successfully created!

You can now take advantage of member privileges to enhance your online shopping experience with us.

If you have ANY questions about the operation of this online shop, please e-mail the store owner.

A confirmation has been sent to the provided e-mail address. If you have not received it within the hour, please contact us.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

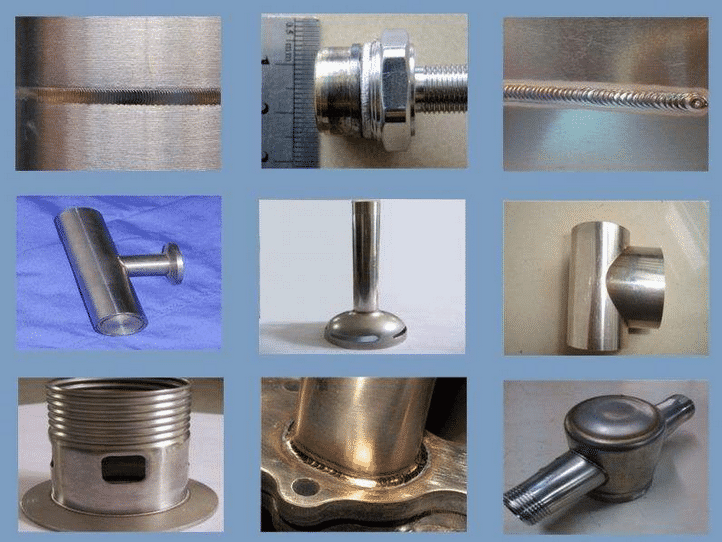

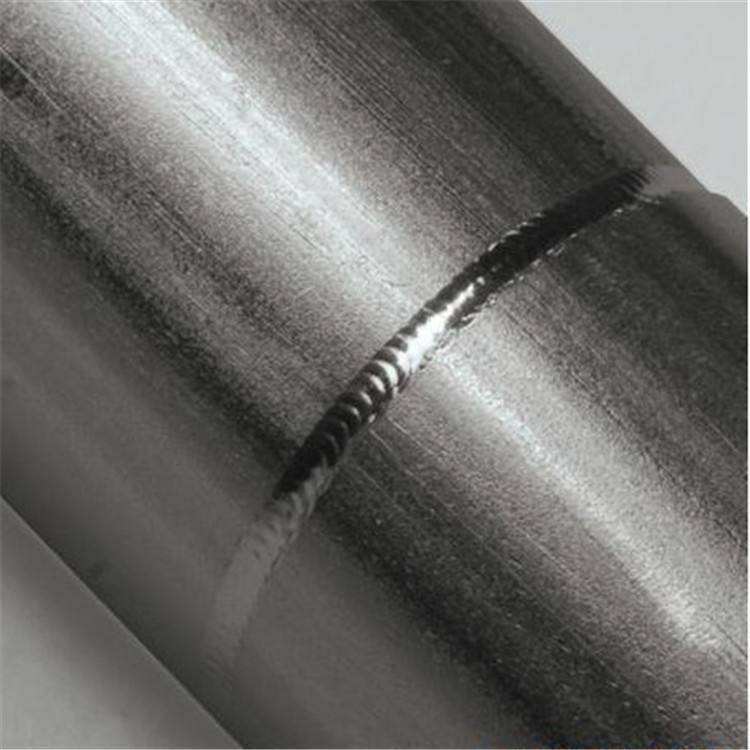

1) The position of the weldment must be accurate and should be controlled in the focus range of the laser beam.

2) When the weldment should be fixed on the fixture, its final position should be accurate at the weld.

4) High reflectivity and high thermal conductivity materials will change laser welding, such as aluminum, copper and their alloys.

5) When laser beam welding of medium and high energy is to be achieved, a plasma controller should be used to eliminate the molten pool around the ionized gas to ensure the reproducibility of qualified welding.

6) The energy conversion efficiency is too low, usually less than 10%.

7) Welding is set by flash, there may be porosity and embrittlement problems.

8) Laser welding machines are relatively expensive.