Returning Customer

I am a returning customer

Register Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Congratulations! Your new account has been successfully created!

You can now take advantage of member privileges to enhance your online shopping experience with us.

If you have ANY questions about the operation of this online shop, please e-mail the store owner.

A confirmation has been sent to the provided e-mail address. If you have not received it within the hour, please contact us.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

Laser marking is related to automotive parts

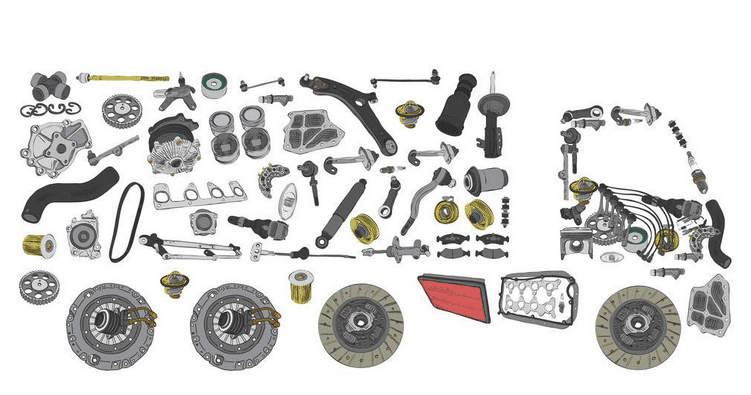

In recent years,advanced technologies represented by laser processing,industrial robots, and digital control are continuously promoting the upgrade of the automotive industry. As an advanced processing method,lasers are destined to bring revolutionary breakthroughs to the development of the automotive industry.

CEO from Raymond Technology Co., Ltd.introduced that laser processing technology has penetrated into all aspects of automobile manufacturing,covering welding,cutting, drilling, marking,heat treatment and forming,and even micro-processing of electronic systems.

Laser welding

Laser welding has become one of the important means in automobile manufacturing because of its advantages such as high energy density, small deformation, narrow heat affected zone, high welding speed, easy realization of automatic control, and no follow-up processing.

There are hundreds of parts in the body and chassis of a car. How to connect them together has a direct impact on the rigidity of the vehicle body. Laser welding can be used to cover almost all metal materials of different thicknesses, brands, types, and grades. Together, it increases the efficiency and quality of production while also increasing the flexibility of vehicle design and material selection.

With laser welding, more stamping parts can be used in place of castings in automotive manufacturing. The use of continuous laser welds instead of discrete spot welds can reduce the lap width and some reinforcing parts, reducing the volume of the body structure itself, thereby reducing The weight of the car body meets the requirements for energy saving and emission reduction of the car.

The use of laser welding can also improve the assembly accuracy of the vehicle body and increase the stiffness of the vehicle body by more than 30%, thus improving the safety of the vehicle body. In addition, laser welding can also reduce the stamping and assembly costs in the automotive body manufacturing process, shorten the production cycle, reduce the number of parts, and increase the degree of body integration.

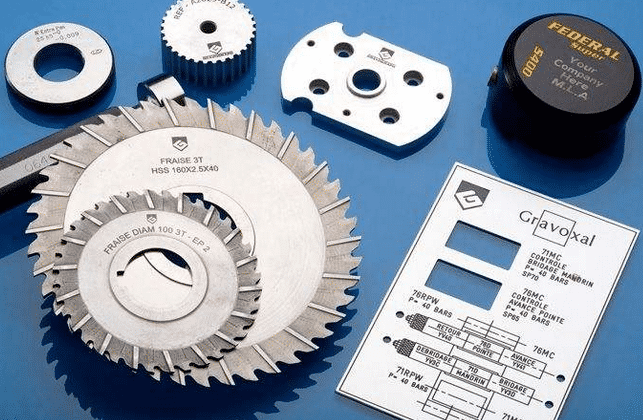

Laser Marking

In the production of automobiles and parts, the establishment of identities is the basis for quality traceability and recall. The uniqueness of establishing the identity of automobiles and parts through marking is critical. Automotive marking has become more and more widely used due to its higher efficiency and adaptability and its permanent nature. Laser marking is a marking method that uses a high-energy-density laser to locally irradiate the workpiece, vaporize the surface material, or undergo a chemical reaction that changes color, leaving a permanent mark.

Laser marking is characterized by non-contact processing that can be marked on any profiled surface without the workpiece deforming and creating internal stresses. Modern auto parts use a variety of materials, including metals, plastics, glass, ceramics, wood, and leather, and the laser can perfectly mark the surface of all these materials.

Of course, the application of laser technology in automobiles is not limited to this. It also involves many technologies such as drilling, heat treatment, surface coating, glazing, forming, reflow processing, model manufacturing, and micro machining, involving product processing and manufacturing. each field.

For more than 130 years, the social role of cars has also undergone tremendous changes. Today, the car is not just a simple means of transportation, it has been deeply integrated into people's lives and work.

With the development of new energy vehicles, there will be some new changes in the manufacturing of the automobile industry, and laser processing technology will inject more vitality into it.