Returning Customer

I am a returning customer

Register Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Congratulations! Your new account has been successfully created!

You can now take advantage of member privileges to enhance your online shopping experience with us.

If you have ANY questions about the operation of this online shop, please e-mail the store owner.

A confirmation has been sent to the provided e-mail address. If you have not received it within the hour, please contact us.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

Common glass painting methods, mainly in the following categories:

Etching method: the use of chemicals - hydrofluoric acid to corrode the glass. First melted with paraffin and cover the glass, carved in the surface of the wax pattern, and then coated with hydrofluoric acid can be washed to paraffin. Since hydrofluoric acid is volatile and polluted seriously, it needs protective layer and its operation is complicated.

Thermal processing: Thermal processing is used to improve the appearance of the quality of processed materials, there are flame cutting, fire polishing, drilling and so on. However, glass brittle high, easily affected by the cracking of high temperature damage to the material.

Screen printing: Screen printing principle is to print the ink to the surface of flat glass, and then use the ink curing measures to make the pattern firm. However, screen printing process complicated, harmful to human body ink, and silk screen is not good color, less color, poor coloring.

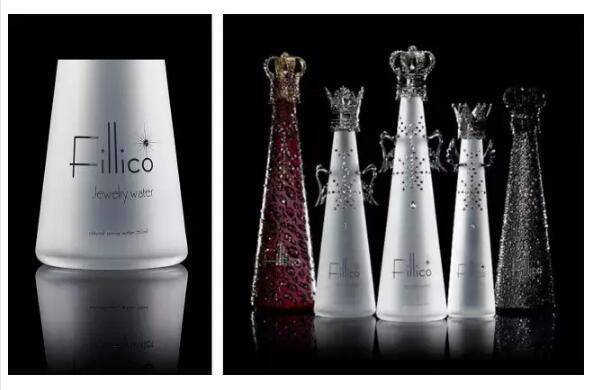

UV laser marking: Laser marking is a photo-motor integrated device controlled by a software system. Produced by software control graphics, using non-contact processing, the glass will not be subject to external damage. And UV laser marking is cold, high beam quality, spot is very small, can achieve ultra-fine glass marking.

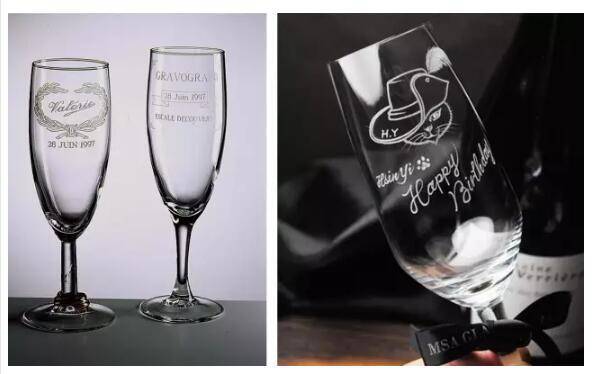

So,UV laser marking for the glass after the color, it will show how the luster it?

UV laser marking machine beyond the traditional processing, make up the past, the processing accuracy is not high, difficult drawing, damage to the workpiece, pollute the environment and other deficiencies, with its unique processing advantages become the new darling of the glass processing, by the wine glass, craft gifts, etc. Industry included in the necessary processing tools. In order to meet the market demand,Raymond unceasingly uv laser marking products to upgrade, and by all glass products business affirmation. Well, today for you simply recommend a paragraph, so that you simply "click" can be free to draw glass products.

If you need UV laser marking machine,please check the link below:

http://www.raymondcoding.com/laser-marking-machine/UV-laser-marking-machine