Returning Customer

I am a returning customer

Register Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Congratulations! Your new account has been successfully created!

You can now take advantage of member privileges to enhance your online shopping experience with us.

If you have ANY questions about the operation of this online shop, please e-mail the store owner.

A confirmation has been sent to the provided e-mail address. If you have not received it within the hour, please contact us.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

If there are product quality problems, manufacturers must take prompt and effective measures.

Failure to take appropriate measures or take too late can increase consumer or customer mistrust and can even make it harder for businesses to survive. In addition, the law on the protection of consumers has also been drafted, and cases of quickly recalling the problematic products as business obligations have also been increasing year by year.

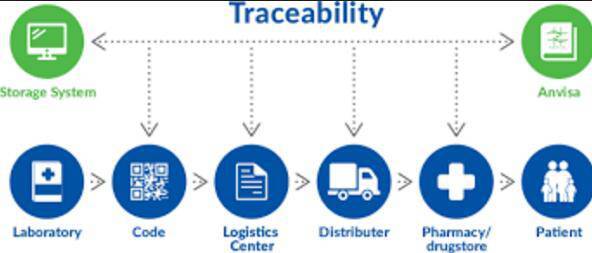

Supply chain traceability:

The general concept of traceability in the world is equivalent to supply chain traceability. Supply chain traceability refers to the ability to track (retroactively) procurement of raw materials and parts to processing, distribution and sales history. The manufacturer can know where the product he is making (= traceable) ", and the downstream process operator or consumer can know where the product" comes from (= traceable). "

Therefore, for manufacturers, traceability has the advantage of investigating causes and recoveries in the event of unexpected problems with the product. In addition, for consumers, traceability can be used as a high-reliability product selection criteria, and eliminate concerns about false labeling.

Traceability:

In terms of traceability, the trend of using accumulated information to track product movements is referred to as forward tracking (tracking), and chronological regression searching for records is called backward tracking (retroactive).

Traceability Identify products on an individual or batch basis and accumulate information in each process. Precisely because such information can be accessed, tracked or retroactively at any time, traceability can begin.

If you have not yet reached the use of high-tech means, do a good job of tracking, then batch and batch first-in-first must be done! Only a good FIFO can make traceability effect.

If you are interested in,please check our website: