Returning Customer

I am a returning customer

Register Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Congratulations! Your new account has been successfully created!

You can now take advantage of member privileges to enhance your online shopping experience with us.

If you have ANY questions about the operation of this online shop, please e-mail the store owner.

A confirmation has been sent to the provided e-mail address. If you have not received it within the hour, please contact us.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

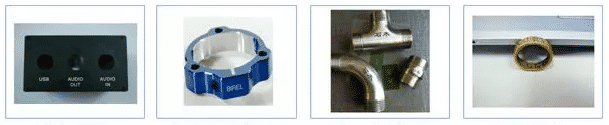

Laser marking technology is one of the largest laser processing applications,the past few decades,the laser marking industry has made significant progress,the most important change in this market is the introduction of low-power pulsed fiber lasers,has now been developed to almost every One supplier can provide such fiber laser marking equipment within the scope of their product offerings

The use of high-energy laser beam irradiation of the material surface, the light heat, the physical or chemical surface of the material, thus forming a mark. With the frequent application of laser marking technology in the field of printing, the scope also includes a variety of materials such as metals,silicon wafers.Fiber laser marking machine easy to use,get people of all ages; In addition,the laser marking also has the following characteristics:

1, permanent; mark will not be due to environmental relations (touch, acidic and alkaline gases, high temperature, low temperature, etc.) and subsided.

2, anti-counterfeiting; Marking using laser marking technology is not easy to copy and change, to a certain extent, has a strong security.

3, non-contact; Laser marking is a non-mechanical "knife" for processing, in any regular or irregular surface printing marks, and the workpiece will not produce internal stress after marking, to ensure the original accuracy of the workpiece.The work surface does not produce corrosion,no"tool" wear, non-toxic, non-polluting,is a clean and pollution-free high environmental processing technology.

4, wide applicability;laser as a processing tool,can be a variety of metals,non-metallic materials (aluminum, copper, iron, wood products, etc.) processing.