Returning Customer

I am a returning customer

Register Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Congratulations! Your new account has been successfully created!

You can now take advantage of member privileges to enhance your online shopping experience with us.

If you have ANY questions about the operation of this online shop, please e-mail the store owner.

A confirmation has been sent to the provided e-mail address. If you have not received it within the hour, please contact us.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

Challenge

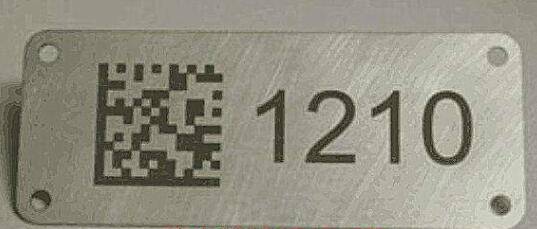

All boxes should be printed with good coding, but not all coding methods can guarantee this. At the same time, companies also need solutions that reduce operating costs to a minimum and ensure the production line is up and running. Our application note assesses the advantages and considerations of using a laser marking system on a box over other coding techniques.

Coding appearance

Advantages: Laser marking can form a clear code on the box. The code of the laser marking machine is clear and easy to read, and can characterize the character tracks completely, which is different from some other coding techniques. Manufacturers of baked goods and cereals can take full advantage of this coding technology to produce accurate, unique and compelling production codes, shelf-lives, logos and other logos.

Durability

To get a clear code, you need to permanently remove the ink from the box. Coding can withstand most abrasion and solvents. Laser marking is usually ruined only by destroying the contents of the package. Because laser marking is instantaneous and permanent, the use of a laser also avoids the need to identify the box or the folding margin that affects the coding, saving a lot of time.

Purchase and operating costs

Benefits: Compared with other coding solutions, the laser marking system minimizes operating costs and reduces long-term total cost of ownership. The laser marking system eliminates the need to purchase inks or solvents and eliminates the need to manage the inventory of these supplies or replace them during production. Laser maintenance frequency is relatively low, can reduce labor costs and downtime costs. In large production environments, operating costs can be significantly reduced.

Diversity and flexibility

Advantages: The laser marking system generates almost any type of coding, including branding, logos and text. With an easy-to-use interface, laser coders can print almost any logo or design. The logo is completely variable and can be automatically adjusted based on time, date, logo unit, or other variable input.Laser marking systems can also be easily adapted to identify packages for different products, customers, package sizes and multiple exit countries and regions.