Returning Customer

I am a returning customer

Register Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Congratulations! Your new account has been successfully created!

You can now take advantage of member privileges to enhance your online shopping experience with us.

If you have ANY questions about the operation of this online shop, please e-mail the store owner.

A confirmation has been sent to the provided e-mail address. If you have not received it within the hour, please contact us.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

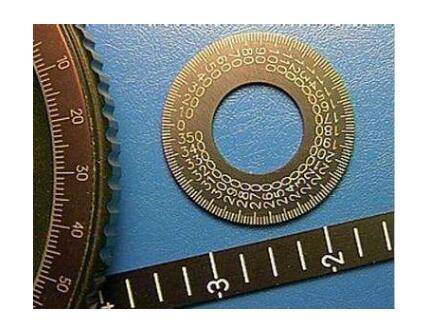

Laser marking machine using the environment:

Equipment working environment: clean / dust-free

Equipment working temperature: 5 ℃ - 35 ℃

Equipment working humidity: 5% -60% no condensation

Power Requirements: 220V / 50Hz / 2A

Daily maintenance

1 Clean the inside of the equipment with dust, dirt, foreign objects, etc. Remove dust, dirt and foreign objects with a vacuum cleaner, alcohol and a dust-free cloth.

2 Check the focal length is within the standard range, the test laser to achieve the strongest state.

3 Check the galvanometer is dirty, wipe the lens paper.

4 Check the laser parameter setting screen is normal, the laser parameters in the setting range.

5 the machine is turned on normally, the total power supply of the machine, the laser, the operation software opens.

6 Look at the ice machine coolant is above the alarm line, down to the alarm line should be promptly added coolant.

7 confirm the emergency switch is normal and effective, press the emergency switch to check the servo is energized.

8 Check to see if there is any laser safety glasses on the marking equipment.

Week maintenance

1 Keep the machine clean The inside of the machine and the machine clean.

2 Check whether the preview of red light can be turned on normally. If the laser parameters are within the setting range, turn on the red correction on the software to turn on the red light.

3 Check the laser cooling water is dirty, the laser cooling water cycle tank water was replaced by pure water (except fiber laser marking machine).

4 on the excitement mirror to do cleaning, first with a special lens paper rubbed with alcohol to wipe in one direction, and then wipe dry lens paper.

5 Check the laser light is normal, open the software on the manual laser to open the laser.

Month maintenance

1 Check whether the guide rail loose phenomenon, with or without abnormal sound, seepage, clean cloth with a clean cloth plus lubricant.

2 to clean the water tank tube attachment, to ensure smooth, unimpeded water pipe joints.

3 Clean the inside of the device with foreign objects such as dust, waste nodes, etc. Remove dust, dirt and foreign objects with a vacuum cleaner, alcohol and a dust-free cloth.

4 Check the laser emitted laser is weakening phenomenon, the use of power meter test.

5 Check the power plug and the connection lines are loose, check each connector site.

6 Check the red preview light path is offset, the red correction.

Half year maintenance

1 Check the machine cooling fan, whether the normal rotation, dust fan and PC computer dust.

2 check the movement of the shaft is loose, abnormal sound, smooth operation, clean with clean cloth plus lubricant.

3 water tank cooling system is normal, check whether the water temperature reaches the set temperature.

Precautions

1 work wear protective glasses, avoid strong light to hurt glasses.

2 special attention, the use of prohibited hand placed in the laser scanning range.

3 When an improper operation of the machine has caused an emergency, immediately press the emergency switch (EMERGENCY STOP).

4 To prevent electric shock, do not wet the hands.

5 laser marking machine can not run the head, hand into the machine, so as to avoid personal injury.

6 No specific parameters shall be freely changed without the permission of the equipment technician.

If you are interested in laser marking machine,please check the link below: