Returning Customer

I am a returning customer

Register Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Congratulations! Your new account has been successfully created!

You can now take advantage of member privileges to enhance your online shopping experience with us.

If you have ANY questions about the operation of this online shop, please e-mail the store owner.

A confirmation has been sent to the provided e-mail address. If you have not received it within the hour, please contact us.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

Glass products have been widely used in construction, medical, chemical, home, electronics, instrumentation, nuclear engineering and other fields. Glass has the characteristics of fragile, so the glass surface sculpture, the process demanding.

Common glass processing techniques are as follows:

Etching method

Use chemicals - hydrofluoric acid to corrode the glass. First melted with paraffin and cover the glass, carved in the surface of the wax pattern, and then coated with hydrofluoric acid can be washed to paraffin. Since hydrofluoric acid is volatile and polluted seriously, it needs protective layer and its operation is complicated.

Thermal processing

Thermal processing is used to improve the appearance of the quality of processed materials, there are flame cutting, fire polishing, drilling and so on. However, glass brittle high, easily affected by the cracking of high temperature damage to the material.

screen printing

Screen printing principle is to print the ink to the surface of flat glass, and then use the ink curing measures to make the pattern firm

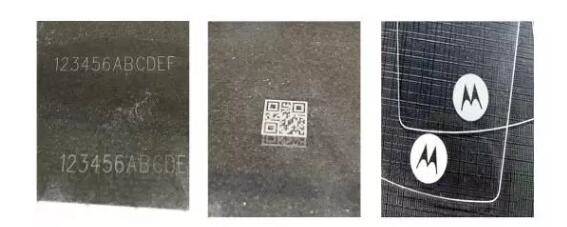

Laser marking is a photo-electric machine integrated device controlled by a software system. Produced by software control graphics, the use of non-contact processing, so that the glass will not be damaged by external forces, perfect glass and fine processing effect.

Laser marking on the glass there are several processes, technology methods are as follows:

Multiple laser radiation method

Using a laser radiation to produce a marked outline on the glass surface, the laser extends a few days to the area outside the original mark to form fragments and then uses multiple irradiations to heat the areas adjacent to the marked area by heat conduction to form these areas Stress gradient, thereby reducing the possibility of secondary rupture, using this method in soda lime glass and borosilicate glass marking is very effective. Containers filled with liquid pharmaceutical small glass, glass in life can use this method of marking.

Discrete points form a ring-shaped crack

Use a series of ring-shaped cracks to form text, bar codes, square or rectangular codes, and other shape code patterns. The common use of this method CO2 laser marking machine more, CO2 laser marking machine set a glass marking code generated by the crack is relatively small. Discrete points appear ring-shaped cracks. Glass heats and cools to produce low-density annular cracks. When heated, the glass expands and compresses the surrounding material. As the temperature rises to the softening point of the glass, the glass rapidly expands to form a dome of a convex glass surface of a low-density material. The use of CO2 laser marking machine, businesses can be beautifully marked in the glass surface pattern, commissioned glass grades.

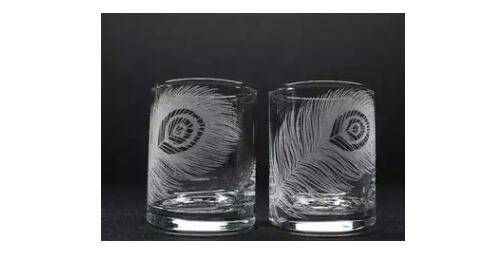

Produce crack-like surface crack method

The use of heating and cooling to change the surface of the glass to which it is applied can not be seen immediately. It begins with a slight amount of pressure and then begins to produce turtle-shaped cracks along the laser marking area. Cracked glass surface not only has the safety of glass, but also play a non-full effect of ice cracking, it is widely used in interior decoration, such as partitions, walls, can also be used for glass furniture, loved by consumers.