Returning Customer

I am a returning customer

Register Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Congratulations! Your new account has been successfully created!

You can now take advantage of member privileges to enhance your online shopping experience with us.

If you have ANY questions about the operation of this online shop, please e-mail the store owner.

A confirmation has been sent to the provided e-mail address. If you have not received it within the hour, please contact us.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

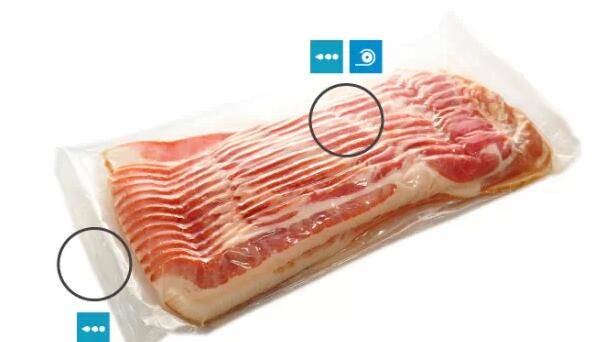

It is well known that meat and poultry packaging plants are extremely harsh in their production environment. Coding machinery often undergo a series of rigorous tests such as extreme temperature and humidity,harsh washing and disinfection processes.The inkjet printer products from Raymond can overcome these difficulties and apply to all your package types, helping you to manage and print batch,batch,date,place of origin and other regulatory requirements for disclosure information.

The technological advancement of MAP has kept the meat in red at all times and can significantly extend the shelf life of meat and poultry products to markets farther than ever before.While this is good for business,the new market also means more coding needs to be managed.With the easy-to-use interface of Videojet,USB-programmable functions and CLARiSUITE network software, it is easy to write or select codes.

Many meat and poultry producers use protective covers to protect their coding equipment in harsh washing environments. However,the only way to prevent water damage is to have certified ingress protection (IP) capabilities.Many enclosures do not have an IP rating and so may not actually be able to provide protection to the printer.Videojet offers a complete line of IP65 printers that eliminate the need for a protective cover to protect against steam,splashing and over-spraying. Rugged printers mean less water damage,less maintenance and longer uptime.

Hundreds of film types for meat and poultry product packaging.Films are usually classified according to the type of barrier they provide,their thickness and their flexibility.They can also be used to create different packaging environments or for various end uses such as freezing or heating directly in the package.Videojet has a full range of inks to choose from to print crisp, long lasting code on virtually any type of film.

Due to the different weight data per unit product,it is difficult to label variable weight products.Usually,the label printer is installed next to the checkweigher to accurately measure and print the weight of the product.However,the use of Coding technology is more cost-effective.Save time and money by integrating weight checker and Videojet printer to record product weight and required shelf life /lot information.