Returning Customer

I am a returning customer

Register Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Congratulations! Your new account has been successfully created!

You can now take advantage of member privileges to enhance your online shopping experience with us.

If you have ANY questions about the operation of this online shop, please e-mail the store owner.

A confirmation has been sent to the provided e-mail address. If you have not received it within the hour, please contact us.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

The challenge we are facing

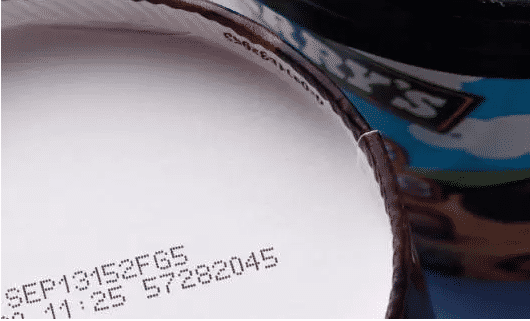

Date and Production Batch Printing with Early Technology,there are many challenges to print:intermittent run time, poor print quality, higher maintenance costs, slow print speeds, and cogging errors caused by human error. In addition, the old inkjet printer start and shut down cumbersome and slow.

Raymond advantage

Continuous Inkjet Printer (CIJ) is the preferred inkjet technology for many dairy applications. Raymond CIJ printers can be routinely used up to 99.9% . Simple ink installation, high level of print quality (instantaneous change in temperature, high speed operation) and unmistakable code selection ensure reliable operation. CIJ can print clear text on countless packaging materials, including plastic and glass bottles, metal cans, sterile packaging, and plastic, paperboard and flexible film containers.

Given the short shelf life of many dairy products, ensuring productivity and product safety is of paramount importance. Clear, easy-to-read coding helps ensure that retailers and consumers securely buy, manage and consume products. The latest inline inkjet printer technology delivers operating efficiencies by increasing uptime, reducing errors, simplifying operations and increasing flexibility to meet changing needs.

No mess, no waste, no mistakes - easier to run day to day

No need to waste time maintaining inkjet printer and putting time into production. Many older printers require operators to add ink and solvent to the internal tank or bottle of ink and solvent into the messy printer cabinet. Splashes of inks and solvents are common and easily lead to mess, resulting in cleaning costs. Accidental mis-packaging of inks and solvents can result in poorly-encoded, expensive printer services and must be discarded with improperly sized products.

Moisture in damp dairy environments is absorbed into the ink system, which can affect the printing process. Moisture in the ink system affects ink stability, causing changes in ink droplet ejection path and print head clogging. Clogged printheads can reduce print quality, lead to printer failure and increase maintenance times. Raymond ink circulation filters unused ink and is designed to reduce the risk of moisture entering the ink system.

Providing consistent, accurate coding is the key to avoiding product waste. Many production lines require the operator to set and select the correct information at the beginning of each batch of production. Raymond coding quality assurance solutions completely eliminate the possibility of costly errors for operators during coding setup or selection. In fact,printers can be integrated into your production management system eliminating the need for manual setup.