Returning Customer

I am a returning customer

Register Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Congratulations! Your new account has been successfully created!

You can now take advantage of member privileges to enhance your online shopping experience with us.

If you have ANY questions about the operation of this online shop, please e-mail the store owner.

A confirmation has been sent to the provided e-mail address. If you have not received it within the hour, please contact us.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

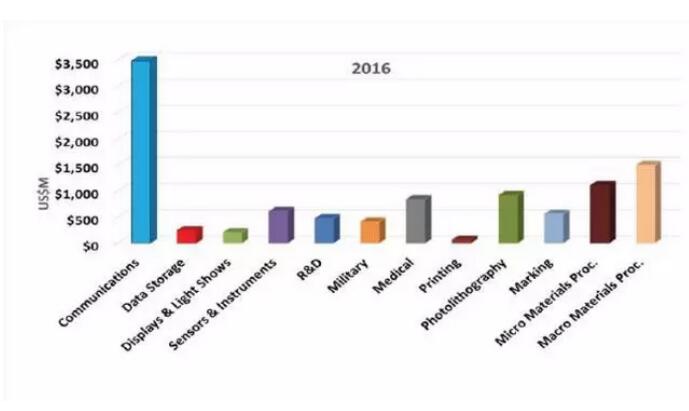

Compared to electronics, semiconductors and other industries, the laser industry is relatively small, 2016 global laser market size of 10.4 billion US dollars,is expected to grow to 11.1 billion US dollars in 2017;China's laser market size of about 60 billion yuan.

Obviously, the laser industry seems to be somewhat insignificant from the market scale; but the application of laser technology is almost able to cover all areas of production and life,from automobile manufacturing, power battery,to mobile phone manufacturing,aerospace,medical equipment and even defense And so almost all of the areas we can think of are active in the laser figure;and for many industries,laser technology has become an indispensable support technology.

As we all know,the core of China-made 2025 is intelligent manufacturing,one of the core of intelligent manufacturing is optoelectronic technology,and one of the core of optoelectronic technology is the laser.Therefore,the laser industry itself, the size of the market is small,but it is driving the development of a major core strength of the manufacturing industry,its importance is self-evident.

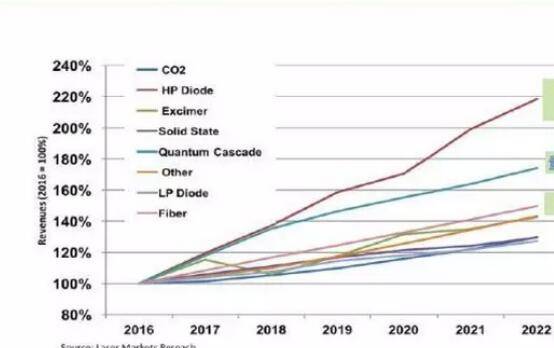

From the market growth point of view,according to the type of laser,the next five years,the fastest growing market is the direct semiconductor lasers,mainly kilowatt-class high-power semiconductor lasers;growth is the second fastest quantum cascade lasers,this laser advantage Obviously,widely used,especially in anti-terrorism,security and other applications play an important role in the future of the global quantum cascade lasers will have a huge demand. Fiber lasers will always maintain a steady growth rate.

From the application of the laser market, to remove about half of the optical communications market,the current macro-processing is the largest market, followed by micro-processing, the future with the manufacturing industry continues to high-end development,micro-processing market will have a great growing space.

In the laser micromachining market,the total size of the global laser micromachine market in 2016 was approximately $ 1.1 billion,and is expected to grow to $ 1.3 billion in 2017. At present the largest application market is the semiconductor / PC board / display processing market,serving the field of the main companies are related companies.Followed by the precision metalworking market,the nonmetallic processing market and the increased material manufacturing market.

The laser used in laser micromachining applications,mainly excimer lasers,fiber laser CO2 lasers and solid-state lasers,where fiber lasers and excimer lasers are the most used.It is worth mentioning that,CO2 lasers did not die from the market,in fact, recently in the non-metallic processing also ushered in a lot of new opportunities.

Another market for laser processing is the kilowatt-class high-power laser processing market,which in 2016 was about $ 1.5 billion, showing a relatively steady growth in the next five years.

In kilowatt-class applications,the current metal cutting applications are still large head,accounting for about 70% of the share, the other two applications are metal welding and weighting manufacturing.

Although the industry is expected to predict the future of the metal welding market is expected to exceed the cutting market, but the next five years,from the sales point of view, the fastest growing or metal cutting applications,is expected to 2022, kilowatt-class fiber lasers in metal cutting applications Harvest $ 700 million in revenue.At present,with the development of fiber lasers,laser cutting machine has made a standard product.

Look at the global laser marking market. This is a relatively mature and stable market, the total income of about 600 million US dollars,the future market growth is relatively slow.Currently used for marking the laser is mainly fiber lasers (about half of the market) and CO2 lasers (about 1/3 of the market),the application of semiconductor lasers are gradually increasing.

The development trend of the laser

Laser technology as a core of industrial manufacturing driving force,itself is constantly moving forward.To sum up,the laser is toward the "faster, higher, better, shorter" in the four directions.

Higher: the power of the laser is getting higher and higher, the average power has more than 10 million watts. In 2013, the first commercial 100,000-watt fiber laser was installed at the NADEX Center in Nagoya,Japan for the welding of 300mm thick steel plates.Laser cutting applications are also toward a higher power development,laser cutting machine power continues to rise, has reached 8 ~ 12kW.

Better: the beam quality of the laser output is getting better and better,the fiber quality of the fiber laser has reached 100,000 watts of single-mode.In the past year, fiber lasers,disc lasers,direct semiconductor lasers have a significant increase in brightness.

Shorter: the output wavelength of the laser covers a shorter band,and the short wavelength laser has been widely used. Many advanced manufacturing processes require cold processing, such as in the manufacture of smart phones,often need to use short wavelength,short pulse UV laser to deal with.Short wavelength lasers have been widely used in surface marking, semiconductor wafer processing, drilling, cutting and other fields.

Faster: The pulse speed of the lasers is getting faster and faster, and the ultrafast lasers have been developed rapidly. They have been driven into industrial applications by means of simpler structures,more convenient operation, lower cost and more stable performance.

Future potential market

On the future market which new application growth point, has always been the topic of concern.

Laser cleaning: With the enhancement of environmental awareness, a variety of environmental cleaning technology came into being, laser cleaning technology is one of them. Laser cleaning using high-energy laser beam and the workpiece surface to remove the material interaction,the occurrence of instantaneous evaporation or stripping, without a variety of chemical cleaning agents, green pollution.Can be used to remove paint, oil, oxide, cleaning screw, rust, cleaning weld. Laser cleaning in the microelectronics, construction,nuclear power plants, automobile manufacturing,medical care,cultural relics protection, steel rust and mold decontamination,automobile manufacturing, construction and other fields have a huge market space.

Metal 3D printing market:metal 3D printing that is made of high-quality manufacturing,usually using a selective laser cladding (SLM) technology,the use of laser energy to melt the layers of metal powder,and finally made the desired shape. In 2016, SLM system sales of more than 1000,which uses the laser source is mainly fiber laser, disc laser/CO2 laser and femtosecond fiber laser, power range of 30W to 1kW or more. 3D printing of the fine degree is also getting higher and higher,print out the fine structure of the resolution has reached the order of microns.

Lidder: LIDAR market will grow steadily over the next five years,with the main drivers of market growth coming from unmanned aerial vehicles,autopilot vehicles,robots,military and security.

Laser lighting: laser lighting part of the market is car laser lighting,mainly car headlights. BMW,Audi and other well-known car manufacturers have adopted a laser lighting system.Another part of the market is safe laser lighting,such as the night environment for people riding a warning sign.

Laser welding:laser welding will be the first in the automotive manufacturing,high-speed trains and aircraft manufacturing, agricultural machinery and shipbuilding and other areas of the spread,it will be a future growth point.

Laser precision machining and microfabrication:will be another future growth point.

Plz dont miss the market of it.

Want to learn more professional details, plz check our office website.