Returning Customer

I am a returning customer

Register Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Congratulations! Your new account has been successfully created!

You can now take advantage of member privileges to enhance your online shopping experience with us.

If you have ANY questions about the operation of this online shop, please e-mail the store owner.

A confirmation has been sent to the provided e-mail address. If you have not received it within the hour, please contact us.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

Usually when we are hot, we will do this:

Fan cooling

Want a lot of air conditioning, can also be like this

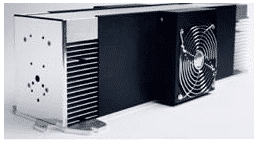

If you are rich, you can also play like this

But the lasers are so precious that we can not put it in the fridge or in the water. How can we help them to cooling?

The existing laser cooling methods include water cooling, air cooling and phase change refrigeration.

1.water cooling

Water cooling generally used deionized wateras a heat transfer medium , which is the main means of high power laser cooling. For example, high-power CO2 lasers for laser processing have an electro-optical conversion efficiency of about 15% to about 25%, and about 75% to 85% of the energy of the working process causes the working gas to heat up.

In addition,the use of circulating pumps can also cause gas to heat.

Due to the large heat dissipation of the high power CO2 laser, it is necessary to install the heat exchanger in the laser gas circulation flow path. The heat exchanger is connected to the chiller to form a cooling water circulation system for heat exchange to ensure the temperature of the working gas in the laser.

Water cooling method requires external water cooling machine, the greater the power of the laser water cooling capacity of the larger, which led to the laser system weight and volume is too large.

Therefore,water-cooled does not apply to the the environmentwhich has harsh requirements of the volume, weight .

2.air cooling

Air cooling generally used gas as a heat transfer medium, through the fan high-speed rotation, forced gas flow quickly, take away the heat generated by the laser to achieve heat dissipation on the laser.

Compared with the water cooling system, air-cooled cooling system without external cooling equipment, with the laser with integrated design, so with a small size, light weight, simple structure, etc., widely used in the output, low-power laser products.

3.Phase change cooling

Phase change cooling is based on the heat loss of the medium during the phase change and its own temperature remains the same property to cooling the laser.

Heat pipe is a representative product of phase change refrigeration technology. The heat pipe shell is made of metal material, and the appropriate working fluid is added to the tube. The working fluid absorbs latent heat from the evaporation section of the heat pipe. The steam flows through the adiabatic section to the condensation section. The working fluid vapor releases latent heat and condenses into the liquid to the evaporation section. The heat pipe is installed in a key area such as the internal heat source of the laser, usually in conjunction with air-cooled heat dissipation to orient the heat generated internally and efficiently to the laser housing for cooling dissipation.

According to the internal structure, the heat pipe is divided with suction core and gravity heat pipe, with a suction core heat pipe manufacturing costs are high, although the low cost of gravity heat pipe, but the installation method has stringent requirements.

Therefore, it is necessary to select a suitable heat pipe according to the application, structure and use environment of the laser.