Returning Customer

I am a returning customer

Register Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Congratulations! Your new account has been successfully created!

You can now take advantage of member privileges to enhance your online shopping experience with us.

If you have ANY questions about the operation of this online shop, please e-mail the store owner.

A confirmation has been sent to the provided e-mail address. If you have not received it within the hour, please contact us.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

Flame cutting as the original traditional way of cutting because of its low investment,in the past,demanding on the quality of processing is not high, when asked a higher quality,a machining process can be resolved,and market is very large. It is now mainly used to cut more than 40mm thick steel plate.Drawback is heat deformation is too large, the slot is too wide,waste material,processing speed is too slow, only for roughing.

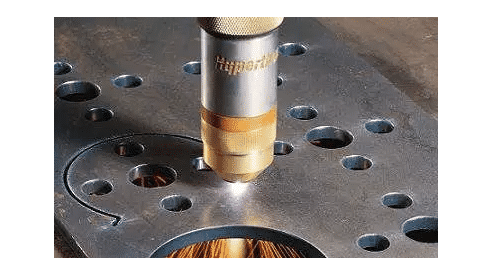

Plasma cutting and fine plasma cutting with flame cutting is similar,heat affected area is too large,the accuracy is much larger than the flame cutting,the speed is much improved,and then it became the main force in the plate processing.China's top CNC precision plasma cutting machine on the line of the actual cutting accuracy has reached the lower limit of laser cutting,cutting 22mm carbon steel plate to reach the speed of 2 meters per minute,and cutting the surface smoothly,the best slope can be Control within 1.5 degrees,disadvantage is thermal deformation is too large,slope is also large,could not cutting with high precision,consumables are more expensive.

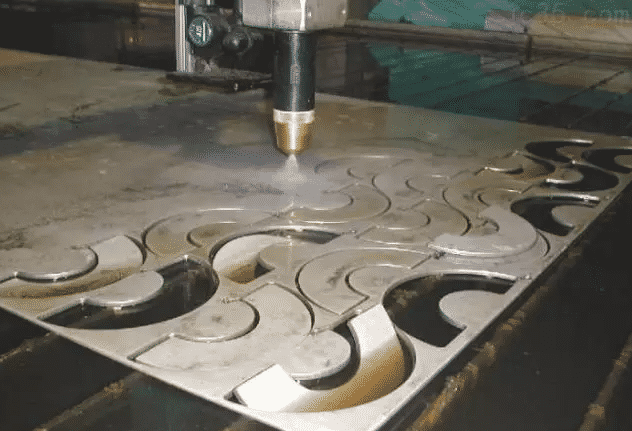

High-pressure water cutting is the use of high-speed water jet doping in the implementation of the sheet metal diamond cutting,it is almost no restrictions on the material,cutting the thickness of almost 100mm or more,the ceramic,glass and other materials when the heat is easy to burst Can be cut:copper,aluminum and other high-reflective material on the laser water knife can be cut:and laser cutting there is a big obstacle.The shortcomings of water cutting is the processing speed is too slow,too dirty,not environmentally friendly,also need consumables.

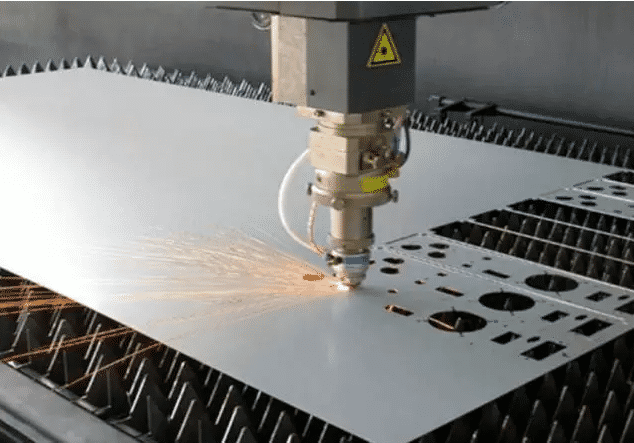

Laser cutting is a sheet metal processing technology revolution,is the "processing center" in sheet metal processing.Laser cutting a high degree of flexibility,fast cutting speed,high production efficiency,product produce cycle is short,those advantage win a wide range of markets.Laser cutting no cutting force,no deformation of the processing;no tool wear,good material adaptability;whether it is simple or complex parts,can be used laser a rapid rapid cutting;its narrow cutting,high cutting quality,high degree of automation,operation is Simple,low labor intensity,no pollution;can automatic cutting nesting,nesting materials,improve the utilization of materials,low production costs,good economic returns.The technology has a long effective life,currently in foreign super-2 mm plate mostly laser cutting,many foreign experts agree that the next 30-40 years is the development of laser processing technology in the golden age (is the development of sheet metal processing direction)

The Cutting accuracy is the first element to judge the quality of CNC laser cutting machine.

Four factors that affect the cutting accuracy of CNC laser cutting machine:

1.The size of the laser buildup of the laser generator.After the collection if the spot is very small,the cutting accuracy is very high,if the gap after cutting is also very small.It shows that the precision of laser cutting machine is very high,the quality is very high. But the laser beam emitted by the cone, so cut out the gap is also cone.Under such conditions,the greater the thickness of the workpiece,the accuracy will be lower, so the greater the gap.

2.Accuracy of workbench.If the precision of the table is very high,the accuracy of the cutting is improved.So the precision of the table is also a very important factor in measuring the accuracy of the laser generator.

3.Laser beam condensed into a cone.When cutting a item,the laser beam is tapered down,then if the thickness of the work piece is very small cutting the accuracy will be reduced, then cut out the gap will be very large.

4.Material will also affect the accuracy of laser cutting machine.In the same circumstances,cutting stainless steel and cutting aluminum its accuracy will be very different,stainless steel cutting accuracy will be higher,and the surface will be smooth.