Returning Customer

I am a returning customer

Register Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Congratulations! Your new account has been successfully created!

You can now take advantage of member privileges to enhance your online shopping experience with us.

If you have ANY questions about the operation of this online shop, please e-mail the store owner.

A confirmation has been sent to the provided e-mail address. If you have not received it within the hour, please contact us.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

The challenge we are facing

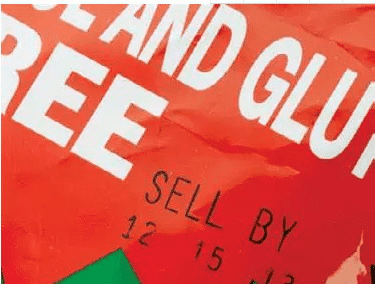

Brand marketing staff very early to understand that competition for the purchase of customer resources to impose a considerable risk. Brand display and packaging is directly related to whether the customer will buy products.Only clean,bright coding to enhance brand appeal to customers,while the poor coding would adversely affect the brand image,Although the coding quality in the brand experience in the proportion is not high,But it is a major factor affecting the sales,therefore,in the brand promotion process should pay full attention to the great effect of the code solution.

Our advantage

Raymond tech understands,Coding quality plays an important role in the visual appeal of packaging,We offer different series of thermal transfer printer (TTO)and consumable,can provide you with high-quality coding,but will not reduce the attractiveness of packaging,We have decades of experience in the snack industry and are also professional in the selection of printers and consumables to help seamlessly integrate the ideal solution into your production line.

Code quality is very important

In highly competitive industries,companies must be highly concentrated,70% of consumers in the retail shelves before making a product purchase decision,Because the decision is usually only in just a few seconds to make,so the packaging of the appearance factor is essential,However,there is no investigation agency that publishes specific research on the impact of poor quality coding on purchasing decisions,but logically,all the factors that can diminish the appeal of the product's appearance are sufficient to increase the attractiveness of the products on the shelves.

The snack industry originally used analogue inkjet technology,including the use of hot stamping machines and roller presses.Both use metal stamps that need to be heated on the module.However,both technologies have the same major drawback that changing the code will cause the device to shut down because it is necessary to cool the stamp first,then replace it manually,then reheat before starting the print job.These methods of coding also often cause the problem of aging or damage,which may lead to poor print quality,and even packaging film perforation problems.The above problems will hinder the production line to run at the best performance,but also cause waste and rework,as well as damage to the critical packaging and brand appeal.

Increase visual appeal and ease of use

TTO is a digital coding technology for flexible film packaging such as snack bags,which not only avoids the problems encountered with traditional analog technology,but also enriches the appearance of packaging to make it more visually appealing.TTO's senior supplier can

1.Simulate preprinted print quality for high resolution code(300 points per inch/12 points per millimeter)

2.Change the height and thickness of the characters in the code

3.The print head is a hard ceramic block,no sharp edges,and will not cause the packaging film to perforate.

Quickly change the encoding

While the progress of this coding technology can enhance the visual effects of product packaging on the shelves,there are a number of other systemic factors(including consumables) before the transition to this technology,

The snack industry faces a unique challenge to the production environment,and the type of bagging machine and the type of packaging are all kinds. In addition to considering the production process, simplifying the integration of existing equipment,the process and the staff of these four aspects,but also carefully assess and plan the above mentioned several factors.

The right solution for high quality coding

TTO is an effective digital coding solution that responds to a variety of challenges and is suitable for snack producers using flexible film packaging.Digital coding technology can quickly and easily change the code online,advanced TTO technology can be configured in the intuitive software system and user-friendly and touch-based controller.These controllers can remove guesses (and possible errors) during the encoding selection process.When the TTO printer is used in conjunction with a high quality ribbon optimized for your production environment, packaging type and code requirements,it is possible for manufacturers to print clean,bright,high-resolution codes that are close to typed print quality.