Returning Customer

I am a returning customer

Register Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Congratulations! Your new account has been successfully created!

You can now take advantage of member privileges to enhance your online shopping experience with us.

If you have ANY questions about the operation of this online shop, please e-mail the store owner.

A confirmation has been sent to the provided e-mail address. If you have not received it within the hour, please contact us.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

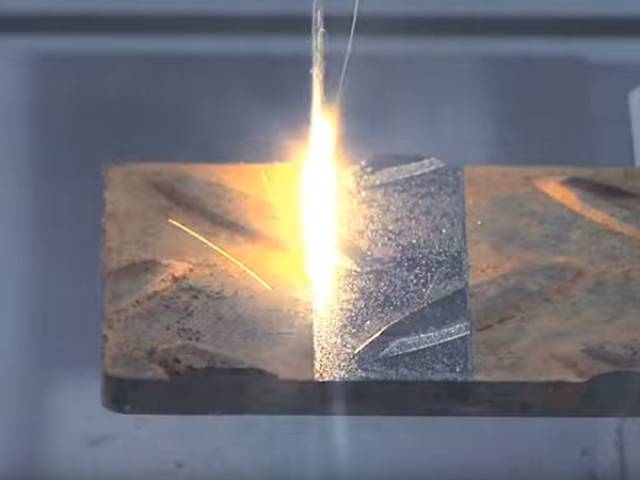

Laser cleaning principle and classification

Traditional cleaning industrial equipment has a variety of cleaning methods, mostly using chemical and mechanical methods for cleaning. Compared with traditional cleaning methods such as mechanical friction cleaning, chemical corrosion cleaning, liquid solid impact cleaning, high-frequency ultrasonic cleaning, laser cleaning has the characteristics of no grinding, non-contact, low thermal effect and cleaning of objects suitable for various materials. Think it is the most reliable and effective solution.

Due to the complex composition and structure of the surface attachments, the mechanism by which the laser interacts is also different. The most commonly used theoretical models for explaining this are the following:

1. phosgenation / photolysis

The laser generated by the laser can achieve high concentration of energy through the concentrating of the optical system. The focused laser beam can generate high temperatures of several thousand degrees or even tens of thousands of degrees in the vicinity of the focus, so that the surface of the object is instantly vaporized or decomposed.

2. Light stripping

The surface attachment of the object is thermally expanded by the action of the laser. When the expansion force of the surface attachment is greater than the adsorption force between the surface and the substrate, the surface attachment of the object is detached from the surface of the object.

3. Light vibration

The pulsed laser with higher frequency and power is used to impact the surface of the object, and ultrasonic waves are generated on the surface of the object. The ultrasonic wave returns after the lower hard surface of the impact, and interferes with the incident sound wave, thereby generating a high-energy resonance wave, causing micro-burst and smashing of the dirt. When the surface of the substrate is separated from the surface of the substrate, the cleaning factor may be selected when the absorption coefficient of the laser beam is not significantly different between the object and the surface attachment, or when the surface attachment is heated to generate toxic substances.

At present, there is no uniform standard for the structure of laser cleaning equipment, which needs to be determined according to the actual cleaning method, the type of substrate and dirt, the effect of cleaning requirements, etc. However, they are still substantially the same in some basic structures. It mainly includes lasers, mobile platforms, real-time monitoring systems, semi-automatic control operating systems and other auxiliary systems.