Returning Customer

I am a returning customer

Register Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Congratulations! Your new account has been successfully created!

You can now take advantage of member privileges to enhance your online shopping experience with us.

If you have ANY questions about the operation of this online shop, please e-mail the store owner.

A confirmation has been sent to the provided e-mail address. If you have not received it within the hour, please contact us.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

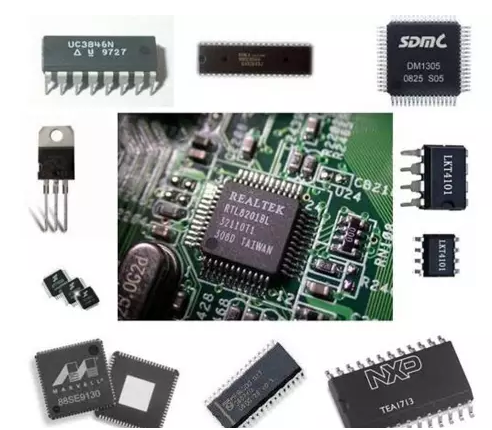

A chip refers to a silicon chip containing an integrated circuit, which is small in size and is often part of a computer or other electronic device. It can form a variety of electronic components on the silicon board to form a circuit to achieve a specific function.

In computer applications, if the CPU is likened to the heart of the entire computer system, then the chipset on the motherboard is the torso of the entire body. For the motherboard, the chipset almost determines the function of this motherboard, and then affects the performance of the entire computer system.

The role of a small chip in the electronics industry is very important, because it not only determines the operation of the equipment, but also determines the industry. In order to identify and distinguish the chip, the surface will be marked with some pattern text to convey important information such as model number, serial number, production number, manufacturer, and origin.

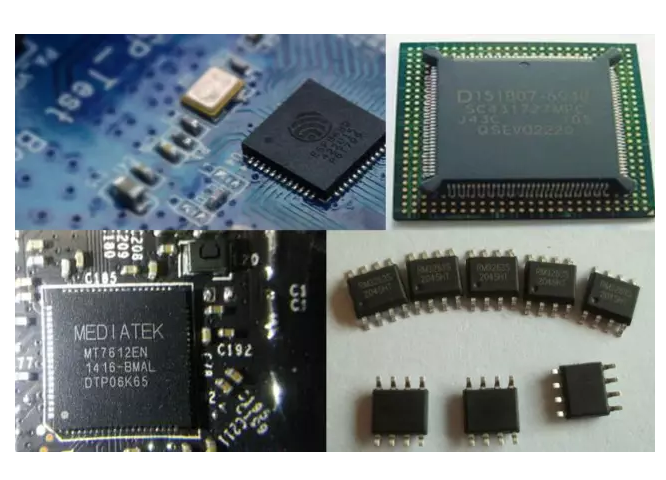

The processing of chip marking mainly includes screen printing and laser marking. The traditional silk screen processing is rough, and the label is easy to fall off to the user and cause inconvenience. In addition, some unscrupulous merchants use potions or erasers to erase the LOGO text on the chip, and to renovate, shoddy, and tamper with the brand. The laser marking machine can make up for the lack of silk screen processing and has become the best processing tool for chip marking.

What are the “flash points” for laser marking on a chip?

High-accuracy—The laser marking is precise and non-contact processing. It can make fine lines less than 0.1mm and characters and numbers within 0.5mm on the surface of the material. It is especially suitable for the identification of electronic chips, which require extremely small figures and texts. .

High-performance - The electronic chip has a large capacity and a high degree of automation. The laser marking device reserves a lot of interfaces and can interface with the product's automated production line control system to make production control more intelligent.

High efficiency - Electronic chips have higher requirements for marking quality, clarity and permanence. The laser marking machine can realize permanent marking of the chips, and does not fade due to external factors such as high and low temperature, acidity, and friction. .

In order to meet the demand for fine marking in the electronics industry, Raymond chip laser marking machine emerged. Its UV laser marking equipment has the advantages of extremely low thermal effect, good beam quality and fine focus spot, and is particularly suitable for marking and microscopic marking of thermal sensitive materials such as electronic chips.