Returning Customer

I am a returning customer

Register Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Congratulations! Your new account has been successfully created!

You can now take advantage of member privileges to enhance your online shopping experience with us.

If you have ANY questions about the operation of this online shop, please e-mail the store owner.

A confirmation has been sent to the provided e-mail address. If you have not received it within the hour, please contact us.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

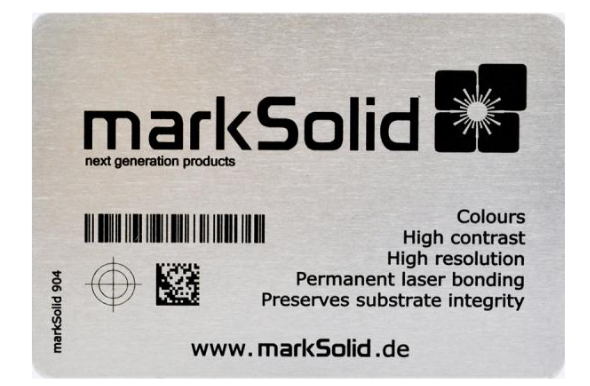

Introduction: When marking the stainless steel material, the laser can adjust the laser beam to change the color change of the surface layer of the material to obtain decorative effects with different colors.

Laser marking technology has led domestic companies to enter the laser processing industry. Especially after fiber lasers are widely used in laser equipment, the laser marking industry has also reached the “peak” of the market. However, since laser marking applications have been used for many years, we have seen common lasers. Marking patterns are black and white gray.

For the current laser marking process, only part of the fiber laser can be used to realize color marking on stainless steel.

In order to mark such a visual effect, in addition to ink jets and color paints, it is also possible to use a pulsed fiber laser with the pulse width and frequency independently adjustable.

When the laser marks the stainless steel material, it can adjust the laser beam to change the color change of the surface layer of the material so as to obtain the decorative effect of different colors.

The advantage is that its pulse width and frequency are independently adjustable. Adjusting one of them does not affect other laser parameters. This is not available in Q-switched lasers. This feature gives the stainless steel color marking endless possibilities. In the actual marking operation, pulse width, frequency, power, speed, filling method, filling spacing, delay parameters and other factors will affect the color effect.

However, due to the fact that the technology is not very mature or has been subject to many limitations, it is also unacceptable to most manufacturers in terms of price. Because a color laser marking machine can buy several laser marking machines.

Laser color marking new technology

Recently, Germany developed a certain laminated material group. The laminated material group includes an external laminated material and an internal laminated material, wherein the external laminated material includes a transparent polymer carrier and is contained in the infrared on one side of the carrier. The zone absorbs the maximum color laser-markable layer of infrared dye. This laminated material can be used for almost all common marking materials. The technical advantage is different from the ordinary laser paper on the market.

A composition that can be used for laser color marking also appears in Japan and its preparation method. The composition components include: 100 parts by weight of the polymer; the content of the laser marking powder is 0.05622 parts by weight; the content of the temperature sensitive substance is 0.16210 parts by weight. The preparation method comprises: melt blending the components including the polymer, the laser marking powder and the temperature sensitive substance according to the group allocation ratio. In the present invention, by adding a warm-sensing substance and utilizing the heat generated in the laser marking process, the temperature-sensitive substance undergoes thermal decomposition, oxidation, and the like at a certain temperature, and these reactions destroy the original substance structure or generate a new substance. At the same time, a new color is produced. This color change is unidirectional and irreversible. After cooling, the original color cannot be restored, so that a stable permanent mark can be formed on the product.

Raymond is working on laser color marking technology. We believe that laser color marking patterns will become more complex and diverse in the future. The exquisite decorative effect will give laser marking a wider application space and become a major trend in laser processing applications.