Returning Customer

I am a returning customer

Register Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Congratulations! Your new account has been successfully created!

You can now take advantage of member privileges to enhance your online shopping experience with us.

If you have ANY questions about the operation of this online shop, please e-mail the store owner.

A confirmation has been sent to the provided e-mail address. If you have not received it within the hour, please contact us.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

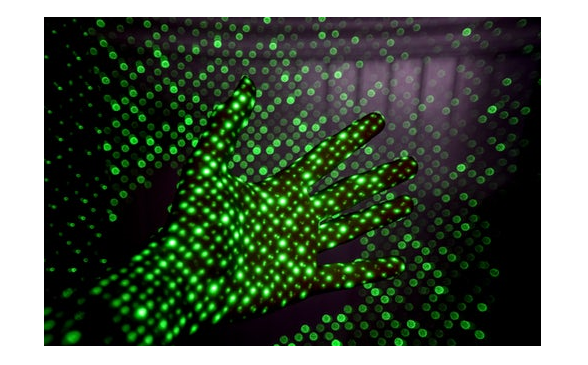

Since the 20th century, following the atomic energy, computers, and semiconductors, lasers have been called another major invention of mankind. It is the "fastest knife", "the most accurate ruler", "the brightest light"...

The principle of the laser was already discovered by the famous American physicist Einstein in 1916, but it was not until 1960 that the laser was successfully manufactured for the first time. In the context of the urgent need for theoretical preparation and production practices, laser came into being. Upon its appearance, it has achieved extraordinary rapid development. Not only has the ancient optical science and optical technology been reborn, but the emergence of the entire emerging industry has also brought about tremendous changes in all walks of life. Lasers are enabling people to effectively use unprecedented advanced methods and means to achieve unprecedented benefits and results, thereby promoting the development and transformation of manufacturing.

At present, the downstream demand of the global laser industry is mainly concentrated on laser processing, optical communication, laser measurement, lasers, laser components, and laser medical treatment. As one of the world's most famous suppliers of advanced production process control equipment, MKS's products are widely used in various semiconductor device production, flat panel displays, optical storage media, glass coating, optoelectronic products and other production equipment and pharmaceutical and medical imaging equipment. MKS forward-looking innovative development, its products have been in a global technological leadership.

Industry 4.0 Forecast: High-end Manufacturing Transformation Brings Major Laser Opportunities

With the integration of smart machines and human experts into a human-machine integrated intelligent system, the traditional manufacturing industry has been gradually transformed toward smart manufacturing. Intelligent manufacturing can perform intelligent activities in the manufacturing process, such as analysis, reasoning, judgment, conception and decision-making. Through the cooperation of humans and intelligent machines, we expand, extend, and partially replace the mental work of human experts in the manufacturing process. It extends the concept of manufacturing automation to flexible, intelligent and highly integrated.