Returning Customer

I am a returning customer

Register Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Congratulations! Your new account has been successfully created!

You can now take advantage of member privileges to enhance your online shopping experience with us.

If you have ANY questions about the operation of this online shop, please e-mail the store owner.

A confirmation has been sent to the provided e-mail address. If you have not received it within the hour, please contact us.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

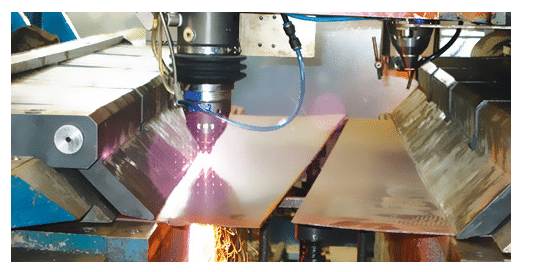

In recent years, laser welding machine as a high-quality, high-precision, low-deformation, high-efficiency and high-speed welding equipment, is becoming an important tool for metal materials processing and manufacturing, more and more widely used in automotive manufacturing and other fields. Laser welding irradiates high-strength laser beam to the metal surface. Through the interaction between laser and metal, the metal absorbs the laser light and converts it into heat energy. After the metal melts, it cools and crystallizes to form a weld.

Because the laser beam has a small focal spot and high power density, it can be welded with some high-melting, high-strength alloy materials. And because the heat affected zone of laser welding is small, the deformation of the material is small and there is no need for subsequent processing. In the process of use, the laser beam is easy to guide, focus, and achieve transformation in all directions, and laser welding production efficiency, stable and reliable processing quality, good economic and social benefits. Various advantages have led more and more companies to use laser welding machines instead of traditional welding.

The traditional welding method takes a long time and has low efficiency. Therefore, in the mid-1980s, laser welding as a new technology received extensive attention in Europe, the United States, and Japan. But to talk about the development of laser welding in our country, we must start from 2002. On October 25, 2002, China's first specialized commercial laser welding blanks production line was officially put into operation. It was introduced by TWB, Thyssen Krupp AG, Germany. In 2003, the first domestic large-scale strip online welding equipment provided by Huagong Laser passed offline acceptance. The equipment integrates laser cutting, welding and heat treatment, making China's Huagong Laser the fourth company in the world capable of producing such equipment.

Laser welding is not the same as laser marking or cutting. Its biggest feature is customization. Laser marking and laser cutting can produce large-scale and batch products, but welding can hardly do this because each customer's needs are very different, making laser welding difficult to mass-produce. However, with the advent of Internet and personalized requirements, the growth of small and medium-sized system integrators and automation companies has increased geometrically, and more and more applications for laser welding have been demanded. This situation will change substantially.

Laser marking used to account for more than half of the entire laser processing market. However, from the development data of the laser industry in 2016, the laser cutting machine market began to break out, and cutting applications began to spread. In the current domestic and international exhibitions, it can be clearly seen that more and more laser companies gradually occupy a larger share. After experiencing the rise of laser marking and the rise of laser cutting, it is believed that laser welding will become The next laser flash point.