Returning Customer

I am a returning customer

Register Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Congratulations! Your new account has been successfully created!

You can now take advantage of member privileges to enhance your online shopping experience with us.

If you have ANY questions about the operation of this online shop, please e-mail the store owner.

A confirmation has been sent to the provided e-mail address. If you have not received it within the hour, please contact us.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

Challenge:

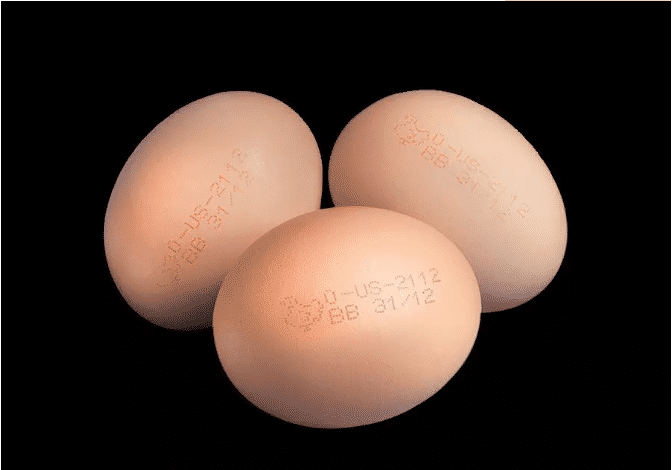

Egg Coding requires the use of special inks to meet a variety of retail and regulatory requirements. Egg producers should pay attention to certain important ink characteristics and at the same time understand how well inkjet suppliers can meet these characteristics.

Compliance

Inks for egg coding must comply with government regulations governing food-marking inks.

These laws and regulations can be broadly stated that inks printed on foodstuffs must be safe for human consumption, whether they are raw or cooked. Egg coding must not damage the eggshell or penetrate the eggshell. After drying, the ink must stay on the surface of the egg shell and will not contaminate the eggs even during cooking.

Quick drying

Egg grading system through the egg very fast.

As the egg is transported on the conveyor belt when the ink code, the ink drying time will not be too long. Completely dry is very important, because fuzzy egg coding may be difficult to identify. The ink dries quickly in less than 4 seconds, ensuring that the information printed by consumers when the carton is open is legible.

Refused alternatives

Because the law requires that inks for egg coding must be food-grade, the inkjet must be replenished with exactly the same food-grade inks and solvents.

Coding eggs with non-food grade inks is considered illegal and can have serious consequences. In addition, adding non-food grade inks and solvents to a designated food grade printer can contaminate the printer, you may need to request service to thoroughly clean the entire printer and replace expensive parts. The result is that the printer can not be used for a long period of time, adversely affecting productivity

Readability

Egg coding must meet the basic requirements of legibility.

Ink colors must be eye-catching enough to be easily seen (red is the most common color). The ink should not spread on the surface of the egg, rendering the code illegible. The ink should be attached to damp eggs and, if necessary, transmitted through the water so that the code will not be erased inadvertently during packaging.

Conclusion

Implementing a reliable cased egg coding system requires careful planning to eliminate interference and maximize performance. With a large team of veterans covering a wide range of sales, applications and service personnel, Videojet can help you find the right egg coding solution.

Our solutions team maintains close relationships with the world's leading egg classifier manufacturers to ensure the right integration. If necessary, we can even enhance our solution offerings to meet your unique operational needs. With this ability, coupled with our extensive capabilities in ink development and manufacturing, we are confident that we can meet your coding requirements for eggs.