Returning Customer

I am a returning customer

Register Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Congratulations! Your new account has been successfully created!

You can now take advantage of member privileges to enhance your online shopping experience with us.

If you have ANY questions about the operation of this online shop, please e-mail the store owner.

A confirmation has been sent to the provided e-mail address. If you have not received it within the hour, please contact us.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

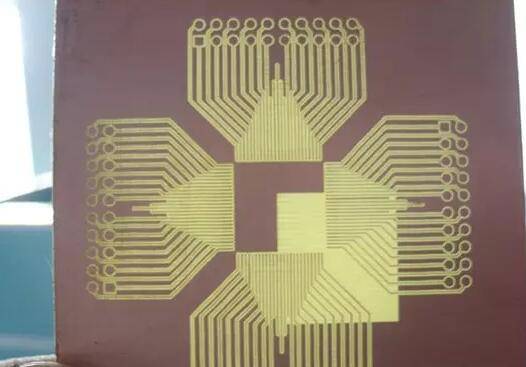

Laser marking machine PCB circuit board industry often referred to as laser laser engraving machine or PCB two-dimensional code laser engraving machine. In the PCB industry, the advantages of laser marking technology reflected most vividly, marked two-dimensional code quality, high efficiency, permanent marking, high consistency, low cost, safe and reliable are widely used.

With the constant progress of science and technology, the continuous improvement of people's living standard, the continuous development of smart phone technology and wearable electronic technology, the smart, light and thin, the miniaturization has become the mainstream, and the consumers' requirements on the quality of products will also become higher and higher , Then as the manufacturer for the inherent PCB circuit board quality control more stringent, we must do excellence, to win the consumer, won the recognition of customers, to achieve secondary purchases, such as Apple, Huawei and other technology leaders.

So how to achieve PCB quality control, which requires the use of product quality traceability system, the commonly used means is through laser marking technology.

On the PCB board identification string, one-dimensional code, two-dimensional code and other information through the camera to identify uploaded to the database, automatically reject unqualified products, to achieve the entire internal process of product quality traceability, from the source supplier information to the product out of the library data Tracking, tracking the entire process, to maximize product quality, and effectively control the production of automated products.

In the early PCB surface string, images, contact information, two-dimensional code and other information are used to achieve the inkjet, but with the continuous improvement of consumer product quality, PCB manufacturers on the PCB board Marking accuracy is also getting higher and higher, as marked clearly visible, small format, enlarge no explosion point, bar code gun clear scale, contains a wide range of information, etc., which became the short board.

With the development of thin and light electronic devices, the PCB board is small in size. In order to save space, the two-dimensional code marked on the PCB board is usually small, for example, a 2 × 2 mm two-dimensional code , And contains more than 20 characters of information, and some of his products such as Top Silver received PCB PCB board minimum two-dimensional code for the 0.8x0.8mm size, this high-density, small format two-dimensional code mark Only laser marking technology can be achieved.

Laser marking technology is more environmentally friendly and inkjet-friendly. Economical and permanent marking will not be easily erased. Non-contact non-destructive marking will not damage the substrate. The processing precision is high, and the minimum is 0.12x0. 12mm 31-dimensional two-dimensional code laser marking, long service life, continuous work more than 100,000 hours, processing efficiency, a two-dimensional code in less than 1 second, the mark is exquisite, the hand touch has no obvious touch above, artificial Easy to operate, fool processing.

Compared with the advantages and disadvantages of integrated laser marking technology and inkjet method, we can see that when a new generation of PCB two-dimensional code mark and laser technology is the perfect partner. Laser marking technology to help the PCB industry to complete the perfect quality control, the broad PCB board for the laser marking machine industry provides a broad space for development.