Returning Customer

I am a returning customer

Register Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Congratulations! Your new account has been successfully created!

You can now take advantage of member privileges to enhance your online shopping experience with us.

If you have ANY questions about the operation of this online shop, please e-mail the store owner.

A confirmation has been sent to the provided e-mail address. If you have not received it within the hour, please contact us.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

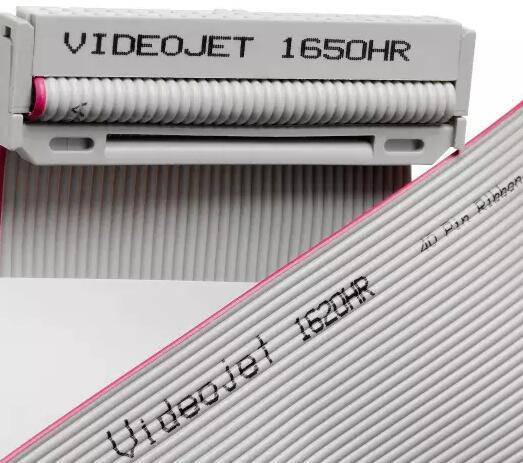

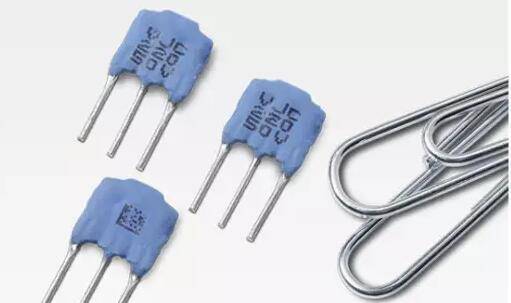

The growing demand for high resolution and contrast printing and small logo windows for electrical components has also created a number of unique coding challenges. Encoding must also be able to withstand chemical corrosion in the production process that can reduce legibility.

solution:

High-contrast, high-resolution permanent coding in small print areas:

The laser marking system removes a layer of material, permanently engraves the component surface and maintains a clean environment

The laser marking was done in a narrow print area with a 37 micron mark resolution

Continuous ink jet printers can use a variety of inks, including high-contrast inks, pigmented inks, and specialty inks that can withstand chemicals such as IPA during the manufacturing process

Can provide long uptime, greatly reducing downtime and increase productivity:

Continuous ink jet printers have advanced features that extend preventive maintenance activity cycles

Laser marking systems provide consistent, high quality marking with minimal user intervention

Manage services and maintenance costs in a variety of ways to help increase uptime and forecast costs

If you are interestedin laser marking machine,please check the link below: