Returning Customer

I am a returning customer

Register Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Congratulations! Your new account has been successfully created!

You can now take advantage of member privileges to enhance your online shopping experience with us.

If you have ANY questions about the operation of this online shop, please e-mail the store owner.

A confirmation has been sent to the provided e-mail address. If you have not received it within the hour, please contact us.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

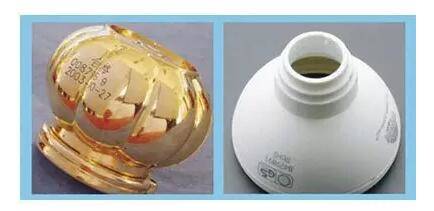

3D laser marking is a laser surface sag processing method. Compared with the traditional 2D laser marking, the requirements of 3D marking on the surface smoothness of the processing object have been greatly reduced. The effect of processing more colorful, more creative processing technology came into being. The use of high-energy-density laser on the workpiece local irradiation, the surface material vaporization or color change chemical reaction, leaving a permanent mark.

Laser marking can mark a variety of text, symbols and patterns, the size of the characters can even reach the micron level. The laser beam for laser marking is generated by the laser. After a series of optical conduction and processing, the laser beam is finally focused by the optical lens, and the focused high-energy beam is deflected to the designated position on the surface of the object to be processed to form a hollow trace.

After several years of development, 3D laser marking technology has gradually begun to mature. Now more and more industries are gradually paying attention to 3D laser marking technology. Excellent performance is favored by many industries and is the hot laser application hot spot nowadays. 3D Laser Marking Unlike previous flat markup, 3D Marking, in addition to some flat markup, 3D Marking can also be done on any curved surface.

Today's 3D laser markers use the current state-of-the-art front focusing method, which is controlled by current computer software to change the laser beam focal length before the laser beam is focused to achieve variable marking of different curved objects .

Because 3D laser markers use dynamic focusing to change the position of the laser beam, many irregular objects can now be laser machined once again, greatly improving work efficiency while also providing excellent processing of these irregularly shaped parts Solutions, for the current product diversification and personalization provided strong support.

At the same time, the current 3D laser marking provides a rapid deep engraving solution. The engraving can be completed quickly without the need for an electric moving lifting platform, which ensures the engraving effect and also provides work efficiency.

Raymond also have one 3D laser marking machine,3D Laser marking machine RMD-PL3D

Features

1, to subvert the traditional 2D marking mode, to achieve the slope, paragraph difference, cylindrical, cone, spherical, and tensile surface and other 3D mark mode.

2, incredible oversized heart angle marking, in the cylinder can hit 117 ° center of the angle of the location.

3, in the marking of the workpiece, the perfect show the target marking graphics, to avoid elongation, tilt and other deformation. So that engraved patterns closer to the original form.

4, so that marking the border is no longer "ignored"! The marking of the various positions on the workpiece is uniform and consistent. 5, subtle filling ingenuity, no matter from any point of view, to see are fine, the ultimate!

6, simple and easy to use that is the United States! Completely independent development of the marking software system, easy to learn and use, WYSIWYG

Product link: