Returning Customer

I am a returning customer

Register Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Congratulations! Your new account has been successfully created!

You can now take advantage of member privileges to enhance your online shopping experience with us.

If you have ANY questions about the operation of this online shop, please e-mail the store owner.

A confirmation has been sent to the provided e-mail address. If you have not received it within the hour, please contact us.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

With the complexity of customer demand functions, diverse market applications, the overall automation and staff to streamline the integration, TIJ inkjet printer gradually into everyone's vision, clearer and more efficient, has become its core two important keywords .

Today, the potential of Shanghai to share with you all the technical aspects of this industry: TIJ Pen Maji is what, as well as analysis of its market applications and trends.

What is its working principle in simple terms?

TIJ In simple terms, we often say that the thermal foam Pen Maji.

Easy to operate and easy to install, thermal printer can print real-time data, barcode, two-dimensional code, database and so on. The editing function is very powerful. You can edit up to 8 lines and exceed 99% Code machine.

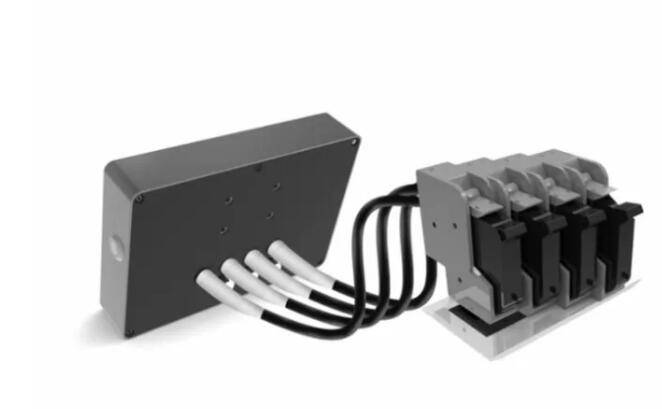

The structure is simpler than the traditional inkjet printer. Usually by the host and power supply, nozzle three parts, do not need filters, do not need cleaning and maintenance, you can achieve long Penma, up to 24 nozzle at the same time work, you can always change the other color ink, such as black, yellow, red, blue , White and other colors.

The principle of thermal foaming Description: The use of thin film resistors in the ink ejector instant ink instant heating (instantly heated to 300 ℃ above) the formation of countless tiny bubbles, the bubble at a very fast speed for large bubbles and expand together to force the ink Spray from the nozzle to form the desired text, numbers, bar codes. Bubbles continue to expand, it will disappear back to the resistor; bubbles disappear, the nozzle ink shrink back. Followed by the surface tension will produce suction, and then pull the new ink added to the ink jetting area ready for the next cycle of printing

A simple analysis of TIJ advantages

First, sealed cartridges. No leakage and waste, pay more attention to cost control, so that customers can use the process to a greater extent, more savings in the procurement costs of supplies.

Second, do not need to use solvents. Compared to the traditional small characters or large character inkjet printer, the use of lower cost, more conducive to printing large quantities of products.

Third, the device does not require maintenance, maintenance, low cost. Around the use of process, TIJ inkjet printer does not require common maintenance, maintenance, just replace the cartridge when the end of the cartridge can be used, greatly reducing the difficulty of customer operation and use, reducing the technical requirements for line workers, more Simple and practical.

Shortcomings and disadvantages of TIJ printer

First, the printing distance requirements. The general requirements of the distance between the nozzle and the product to be controlled within 5mm, in order to achieve the best printing effect display.

Second, the ink used on the material selectivity. This is also the concern of many manufacturers and a headache, such as clarity, adhesion, permeability, etc., TIJ inkjet printers are generally used in paper, plastic, metal, cloth and other surface permeable material.

Third, the high cost of supplies. A 42 ml cartridge box, smaller capacity, the relative price of small inkjet printer ink more expensive.

A Brief Description of TIJ Application Range and Market Development

The reason for the rapid development of TIJ printers is the changes in the market. As more products begin to attach importance to packaging and the popularity of two-dimensional code applications, in our common product packaging (supermarket food, Drink is an early start using two-dimensional code for marketing case).

As more and more QR code printing needs begin to emerge, many manufacturers are looking for marking devices that can batch-print variable codes. TIJ highlights its advantages and gives quick notice of the product, though it has evolved For many years, but was rapid application and promotion in 2015-2017 years.

From the material point of view, are more used in industrial product packaging, electronics traceability itself, as well as various types of container coding, packaging bags, bottle packaging Fu code.

From the industry point of view, food, beverages, cosmetics, cable, building materials, electronics, pesticides, seeds, fertilizers, etc., have begun large-scale application.

Some printers will also purchase a large number of TIJ inkjet printers to meet the needs of large-format printing with the support of customers' demand for variable-format printing. The resolution can reach 300dpi, the ink dot is extremely small and the printing definition standard is reached.

It should be noted here that the TIJ series of machines are mainly suitable for large format, flat surface printing code printing, and for similar to the bottle cap, round objects TIJ is still difficult to break, mainly due to thermal foam printing Just 1-2 mm away from the CIJ (small character) inkjet printer, the print distance is closer and material quality is more sensitive to print quality, requiring more consistent production lines and equipment.

Thermal foam coding technology itself has the advantages of high resolution and high speed, and these two advantages are almost the same end-user needs.

However, the traditional thermal foaming technology has two main application limitations. One is that the high-adhesion printing effect on the non-permeable material is almost impossible to achieve; the other is the short spraying distance. If you can break through these two points, for the traditional Coding equipment market may be a great impact.

In high resolution thermal foam inkjet printer is what] this article,latent profits have done a systematic comparative analysis and explain, as well as the HP nozzle features and applications of universal, from the concept of high resolution Words quickly find the key points in order to achieve understanding, welcome to click on the text at the end of comparison reference.